Charlie..

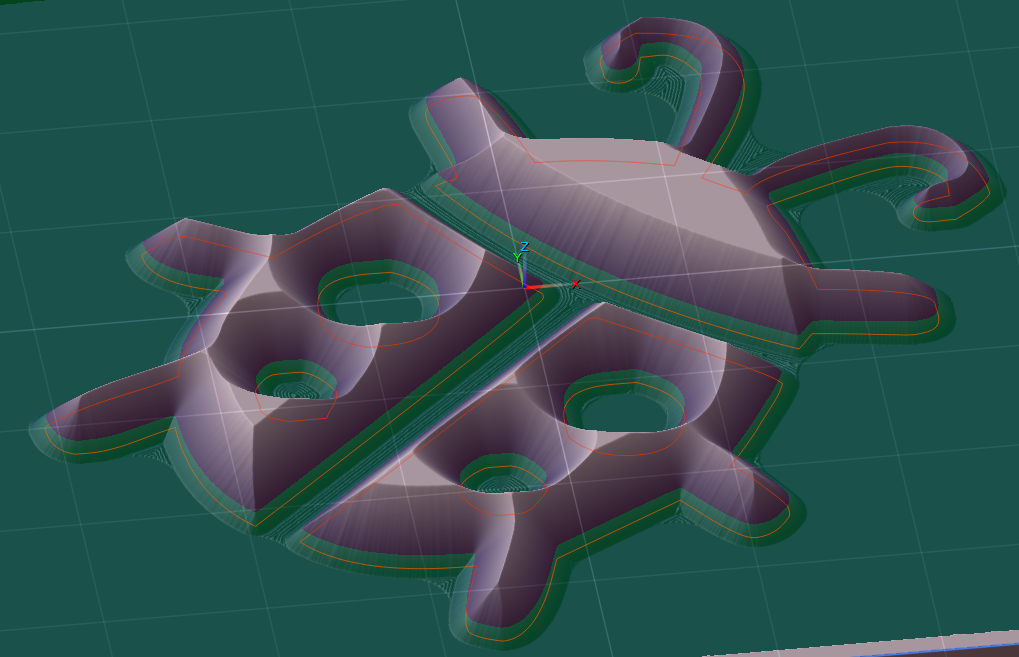

I just started 3d carving using STL files. I was testing some cut files , and was looking at the confine cut option for operations parameter. I understand how it works. For those type of files, confine cuts would be better option to confine it to the STL layer. It could be used for borders and clamping easier . Point out the error of my ways.

Thanks Joe

Charlie....

Charlie.... A bit off topic.... I've been using these for awhile , been great for sanding after cutting. Come in different grits they work well. Alligator looks great.

A bit off topic.... I've been using these for awhile , been great for sanding after cutting. Come in different grits they work well. Alligator looks great.