Hi NicoClock,

When you say you want a toolpath that gradually mills are you referring to a slope at the bottom of the triangle pocket?

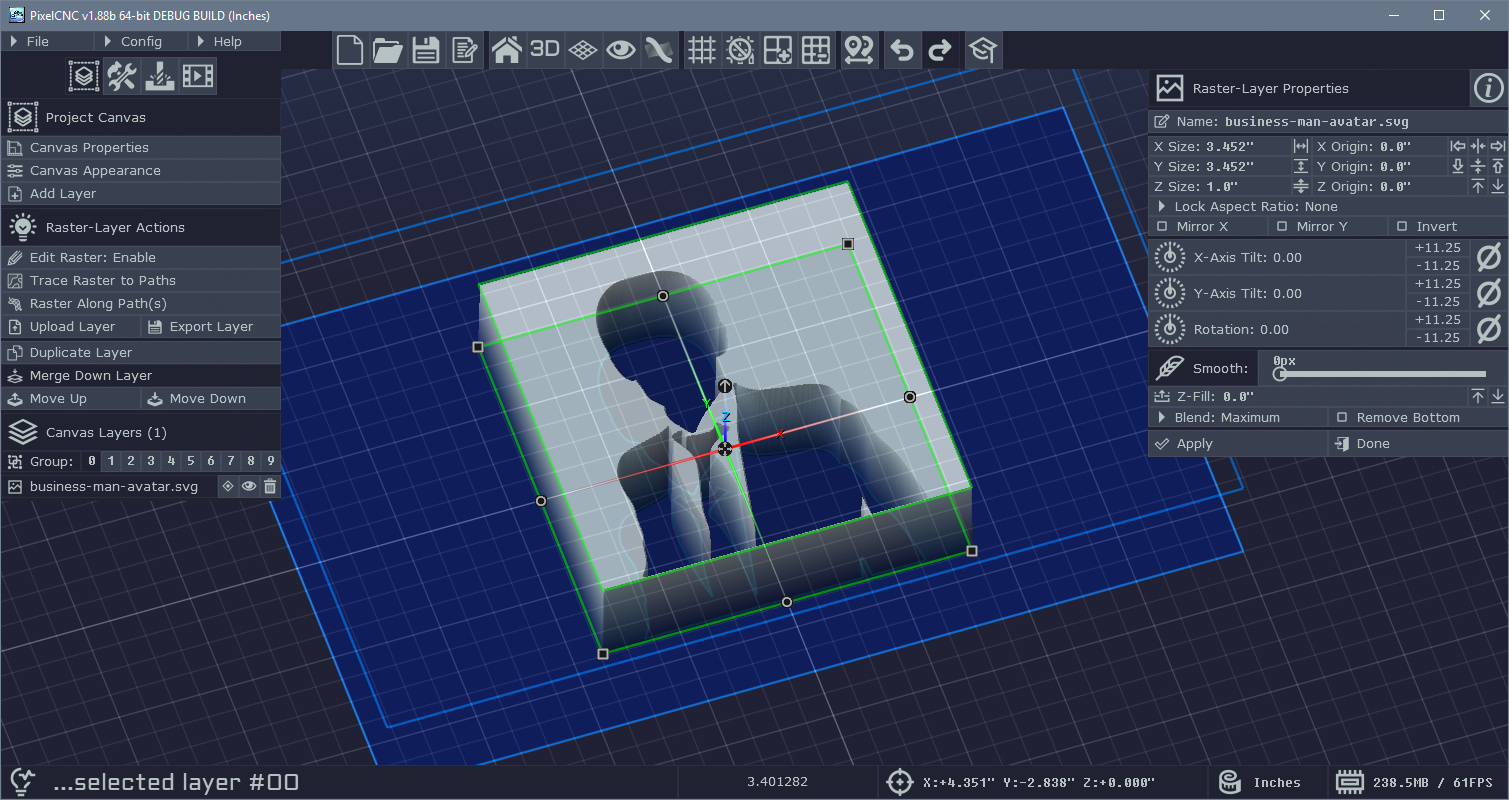

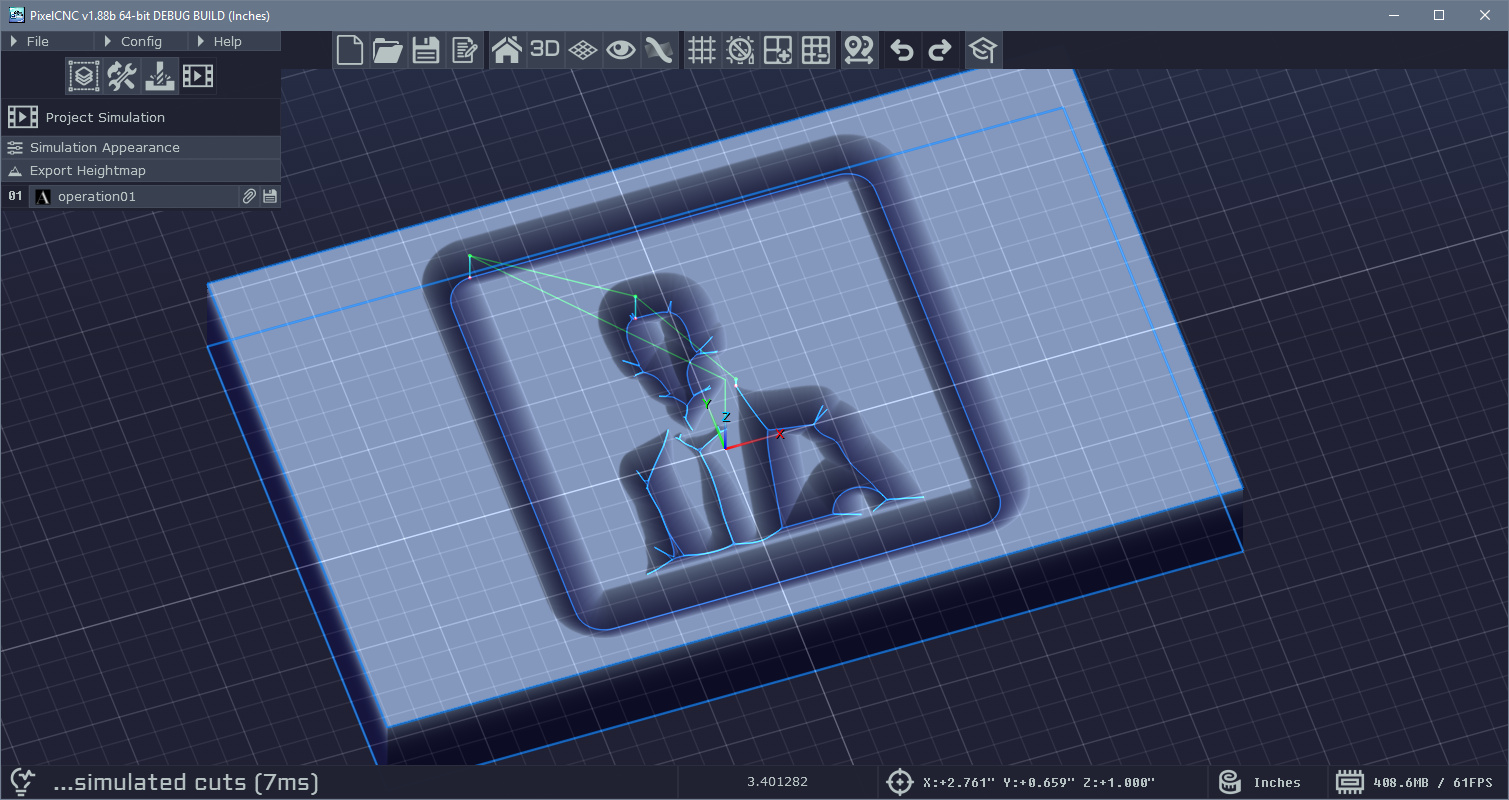

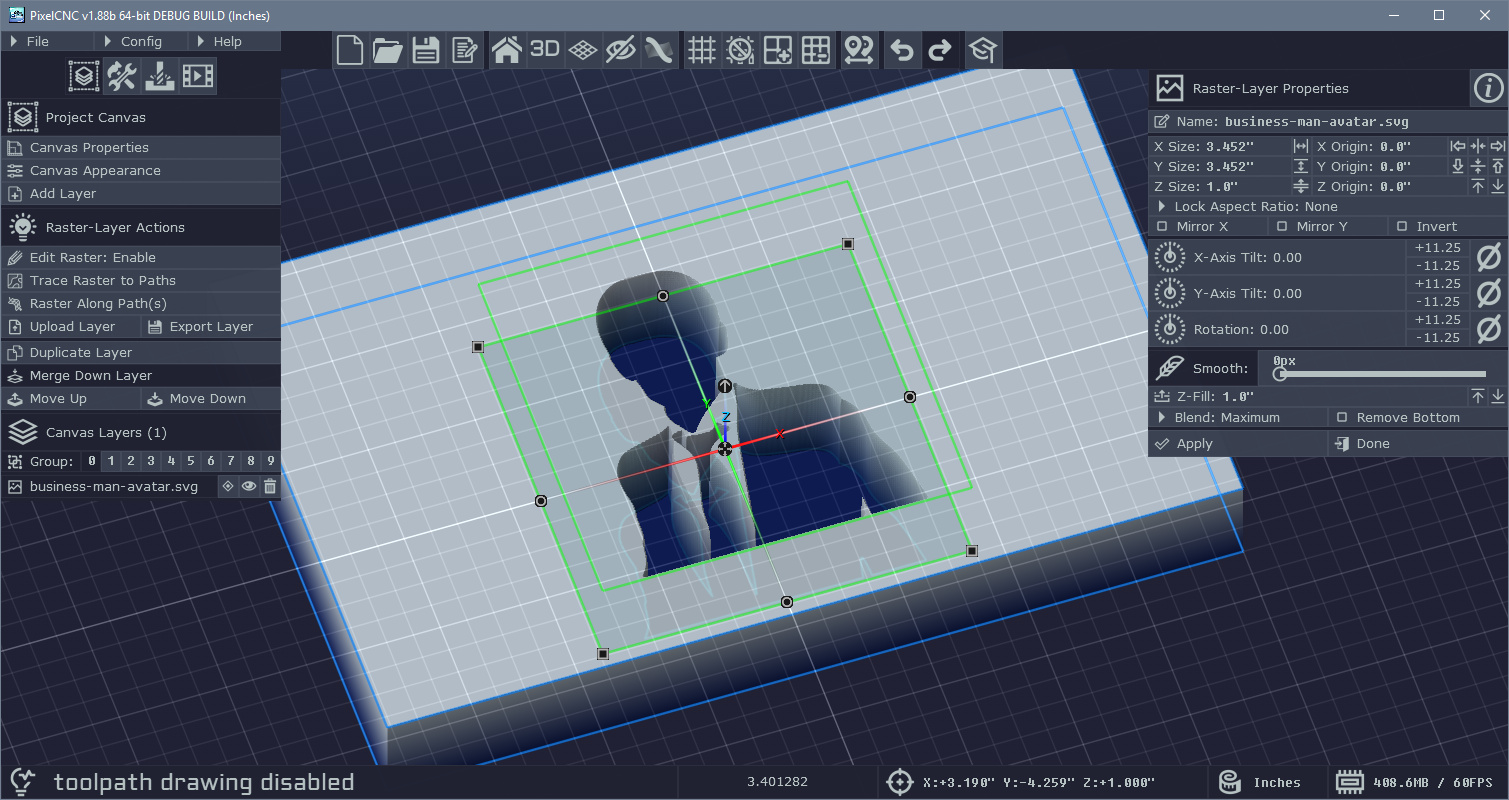

If that is the case you can tilt a blank raster-layer to get a slope, or create a swept shape using the Path Sweep function in the paths-editing mode to sweep a path drawn as a ramp with the desired depths at each end. Then with your triangle path you can use the Shapes From Paths function with the Shape Exterior option enabled to create a raster-layer with the triangle as a pocket. Then your operations would toolpath off of that canvas composition.

Let me know if that will work for you or if you need more detailed information about anything :]

- Charlie