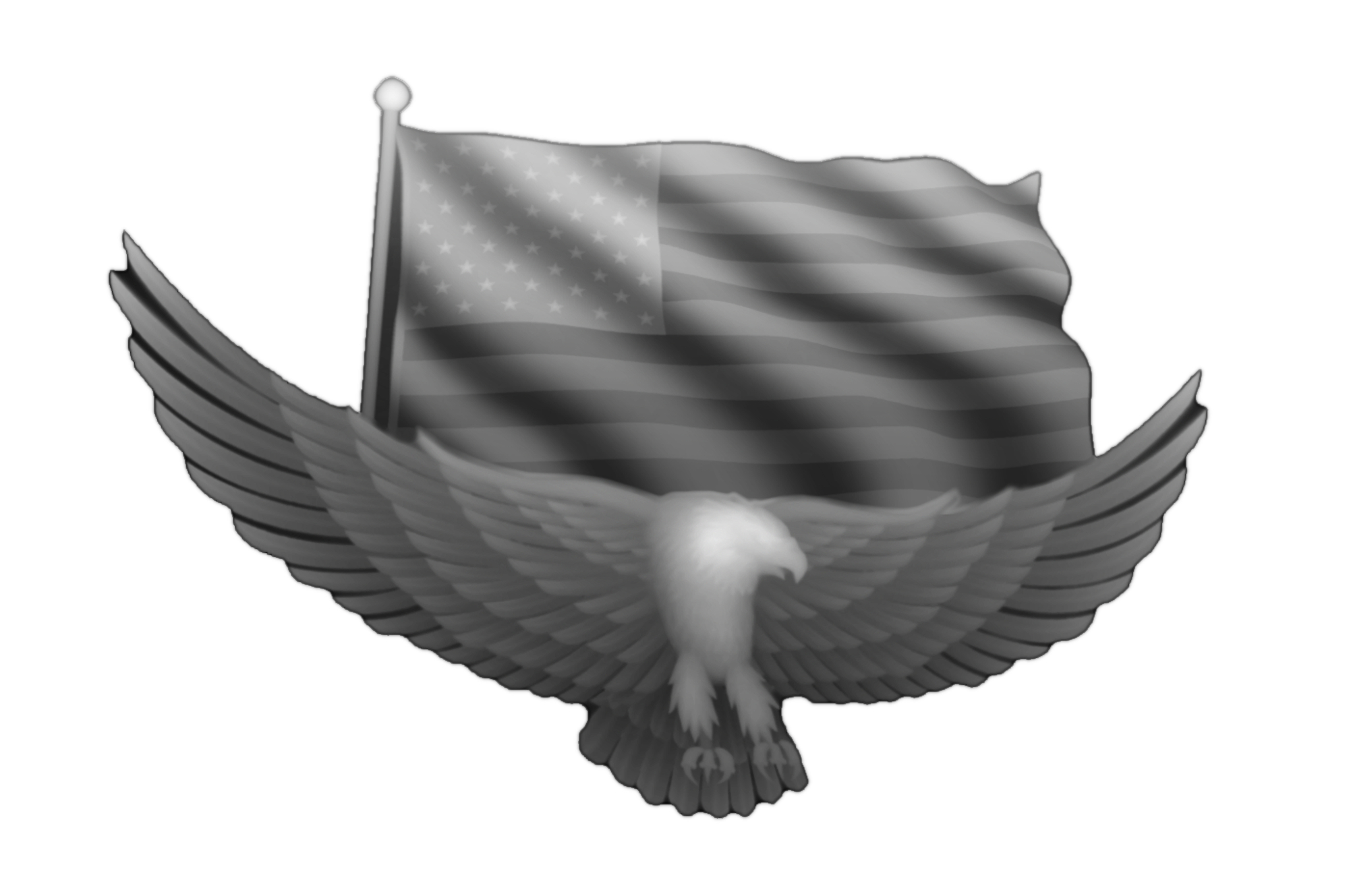

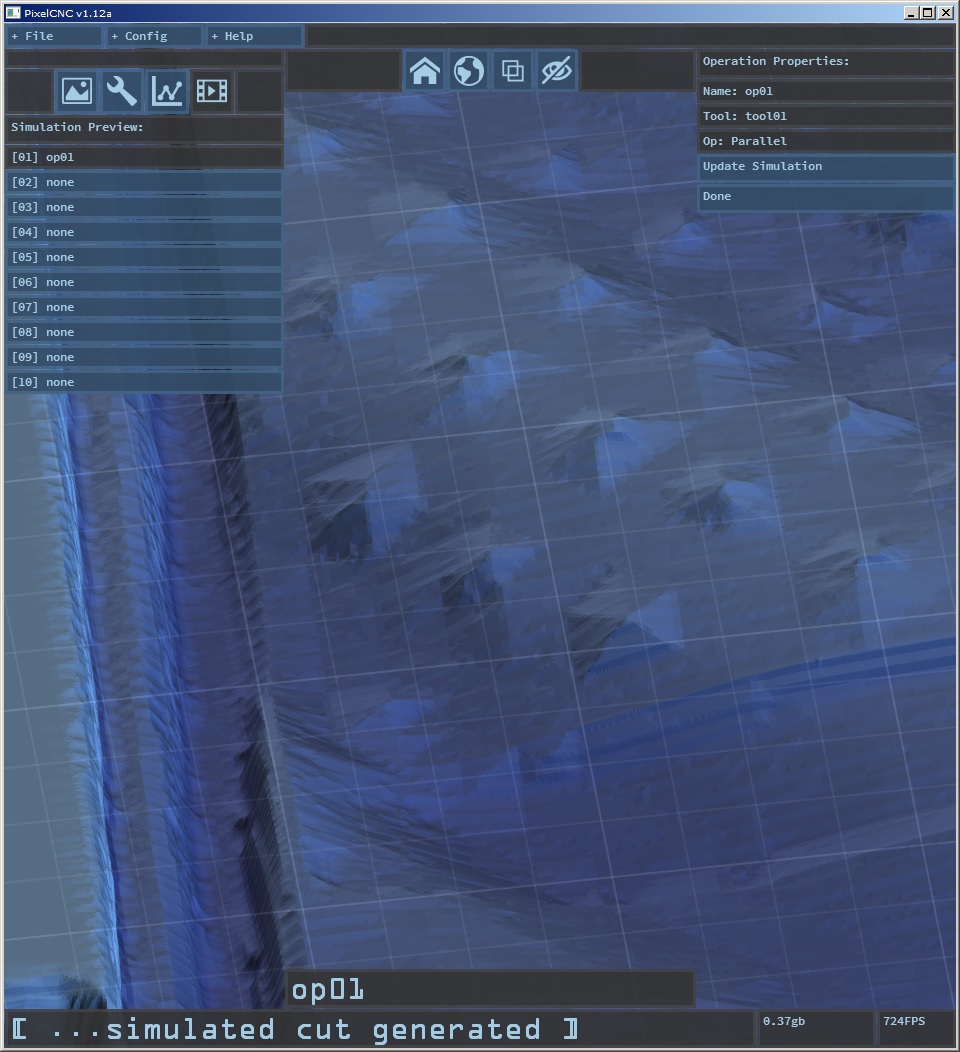

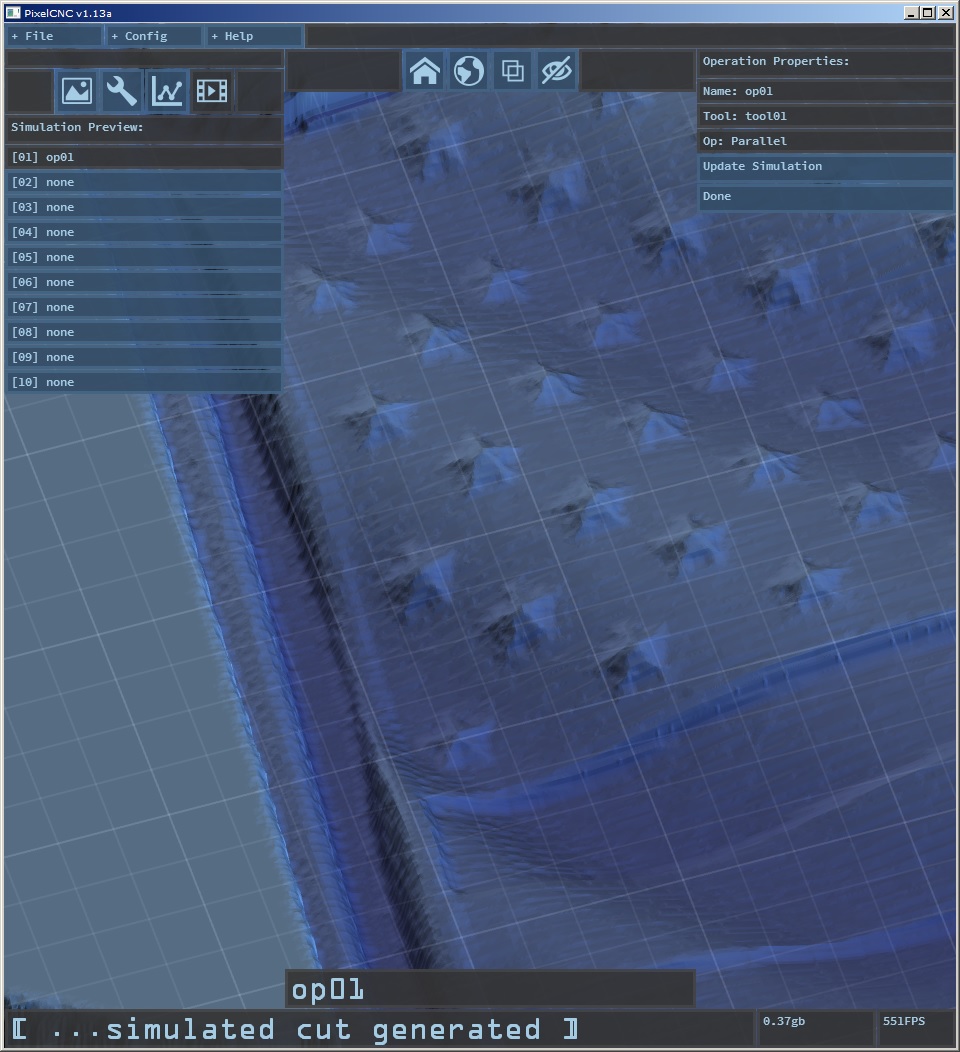

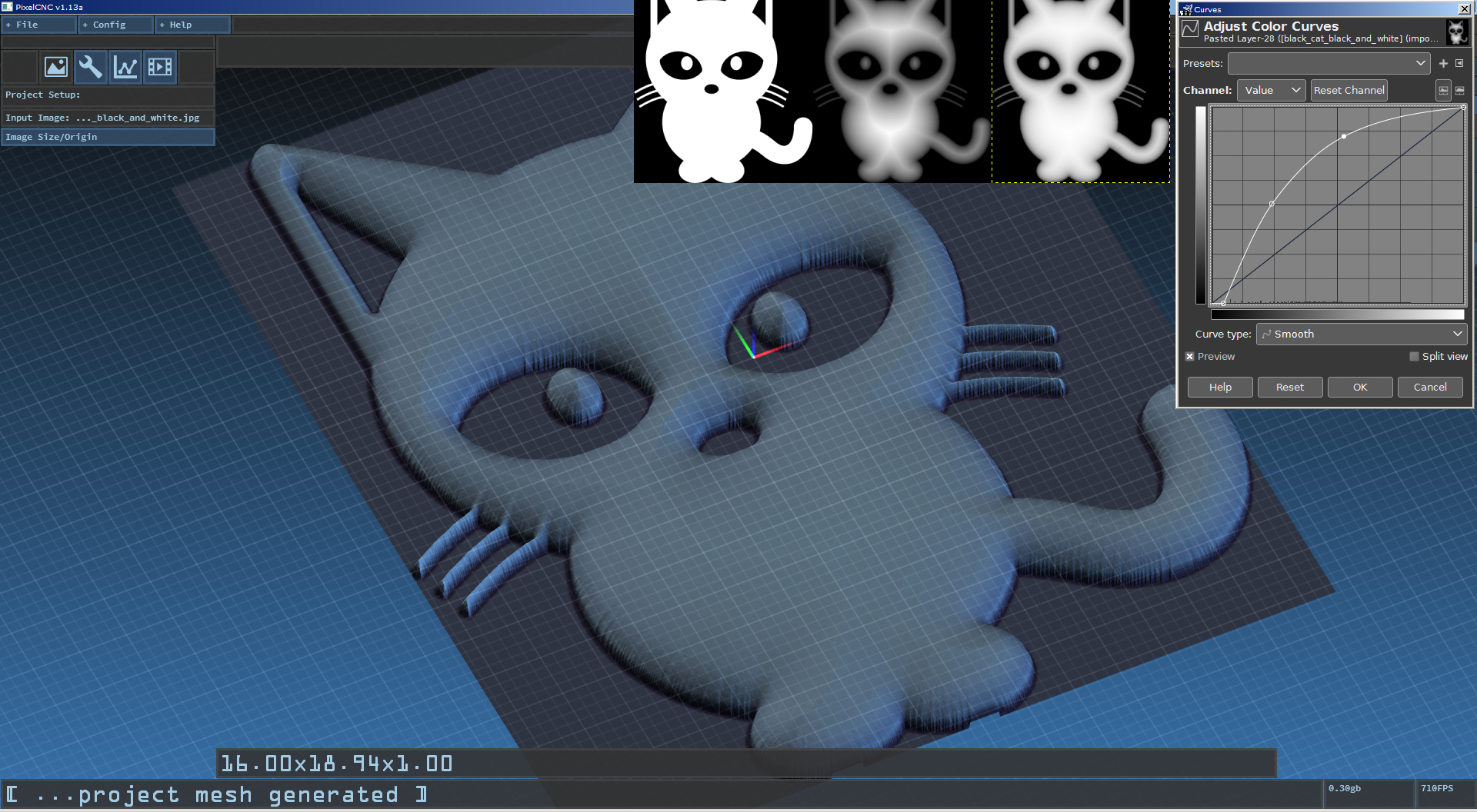

Here is an image that I convert from a .STL image to a .PNG. I would be curious to see what setting you would use to get the best output from PCNC. When I tried using PCNC with this image, the tool paths seems to be a little rough. I tried with a 1/8" endmill, .05 setover at both .25 and .50 max depth.

Thanks,

Donnie