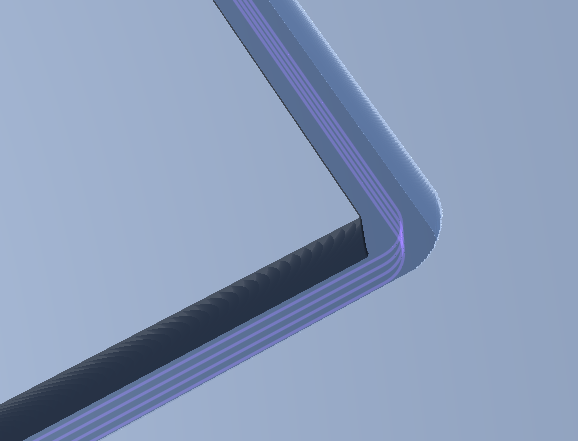

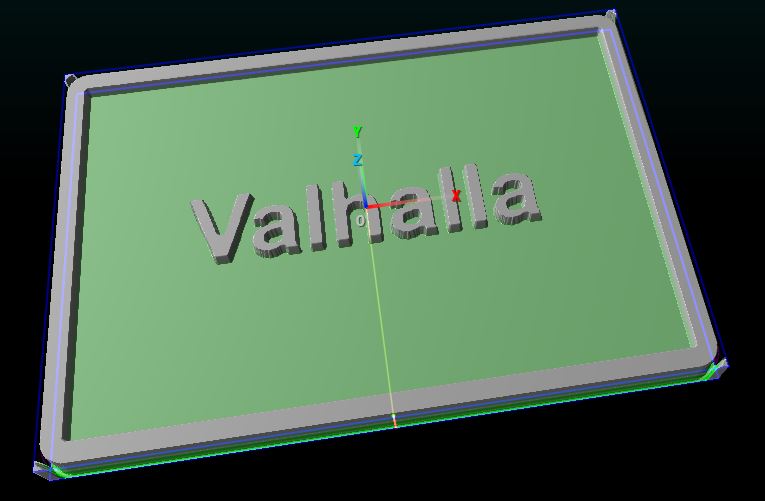

Why am I getting rounded corners on a profile cut out ? How do I get square cuts, I tried a lot of combinations . This was on a Rater layer with a -.5 offset , depth was material height , had it on outline mode with pocket cut . Bit was 1/8 " Endmill