Hey ya'll.

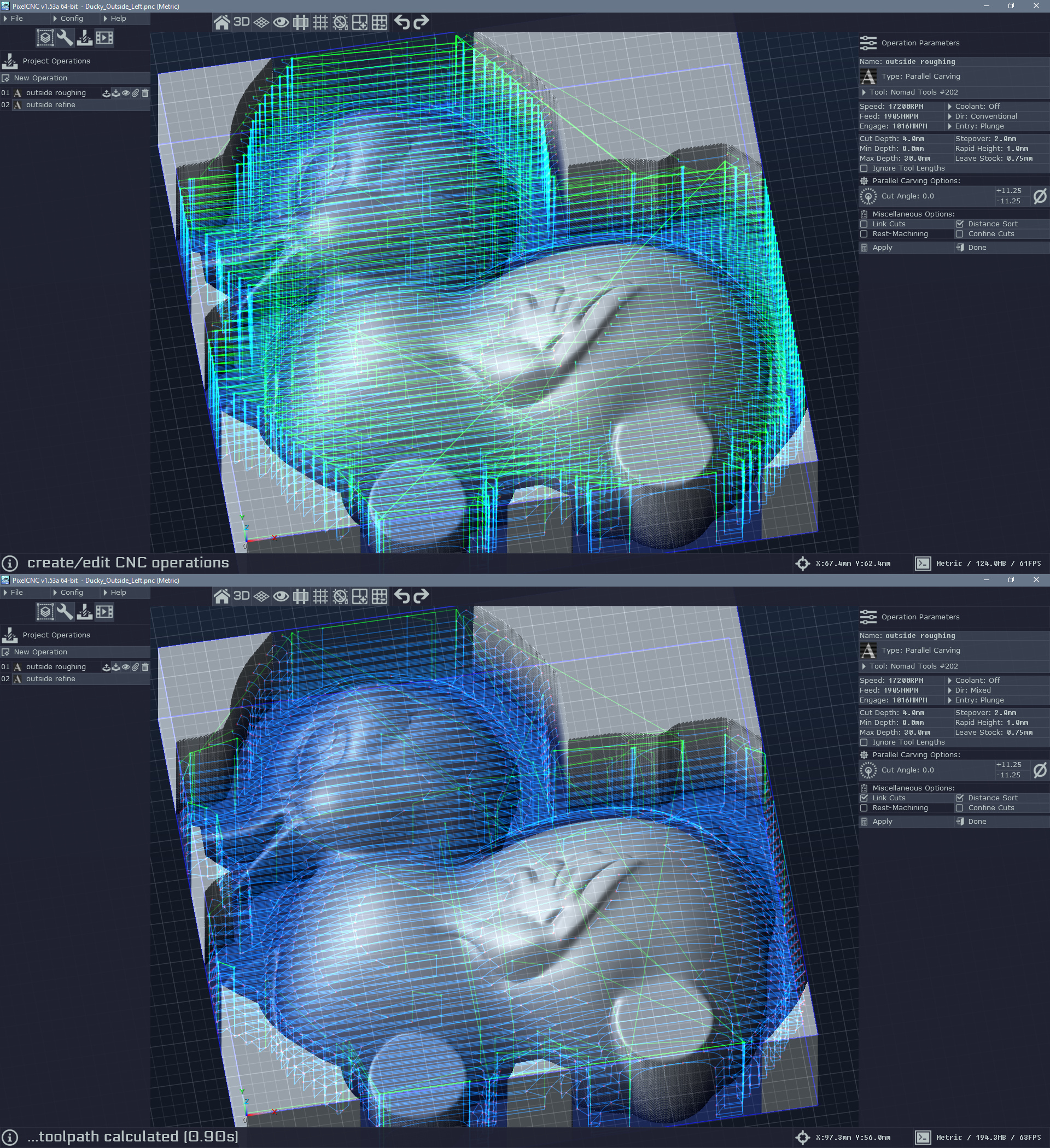

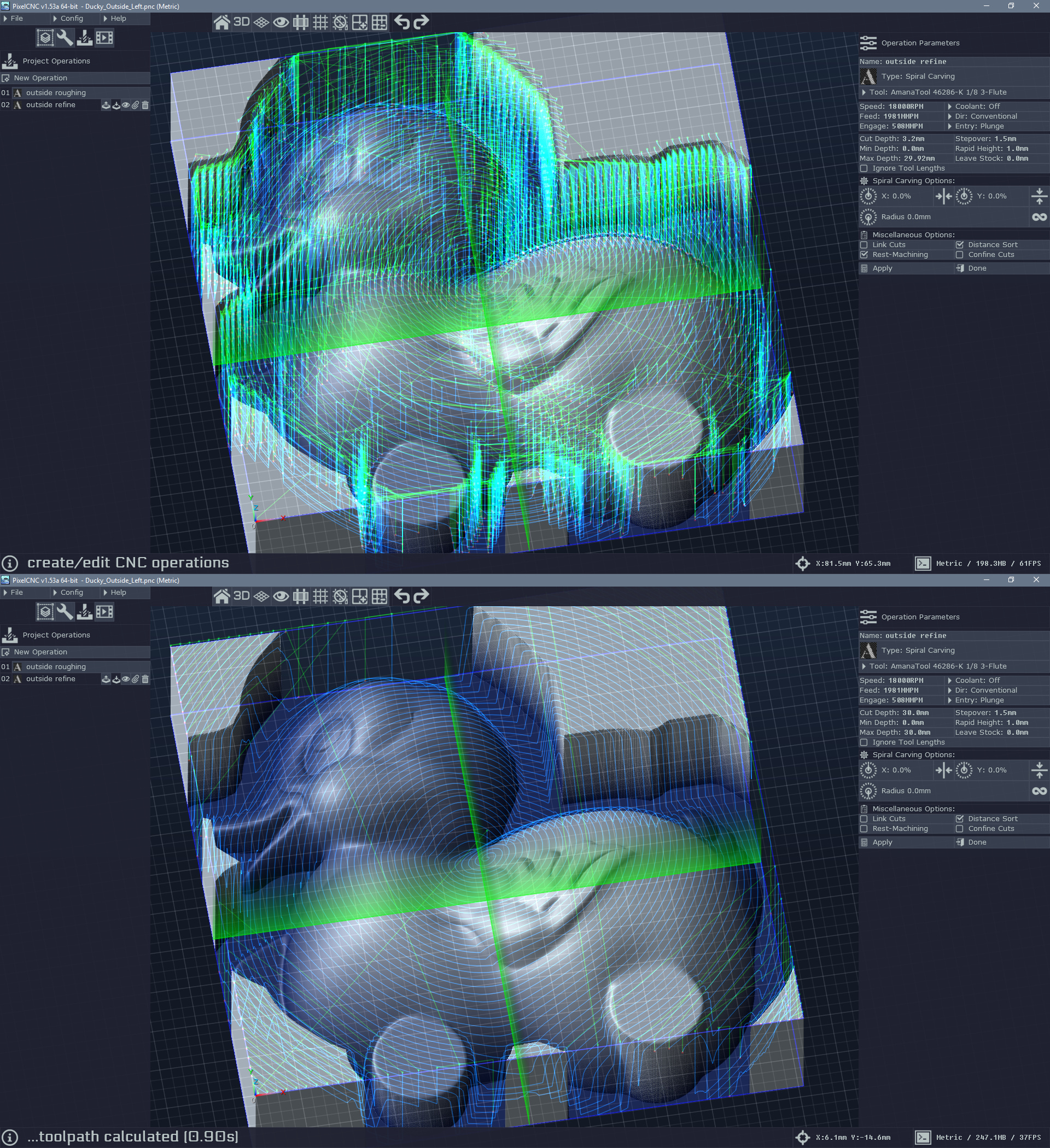

First time posting; love PixelCNC! Here's a ducky I'm working on. I was able to mask off a lot of non-ducky canvas so my roughing cut didn't waste time on it which was great. But then for my refining pass, the toolpath having to visit the edges of that non-ducky portion became a massive waste of time.

A feature to confine toolpaths to a selected area (perhaps defined using a path?), like ducky only, would be incredible. It's much needed.

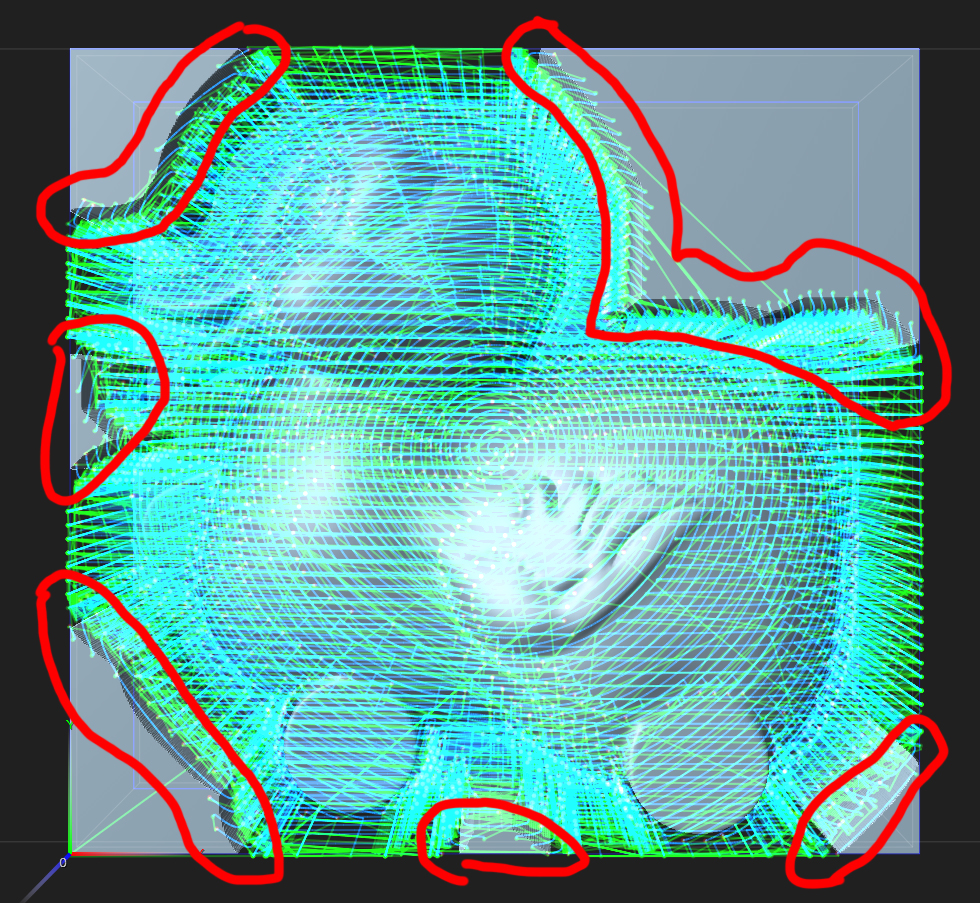

Here I've circled in red the waste areas where the refinement cut is spending time unnecessarily. If there is a way to avoid this issue, please let me know! Cheers.