Ok, I took a look at the ducky project and there was definitely room to speed things up a bit!

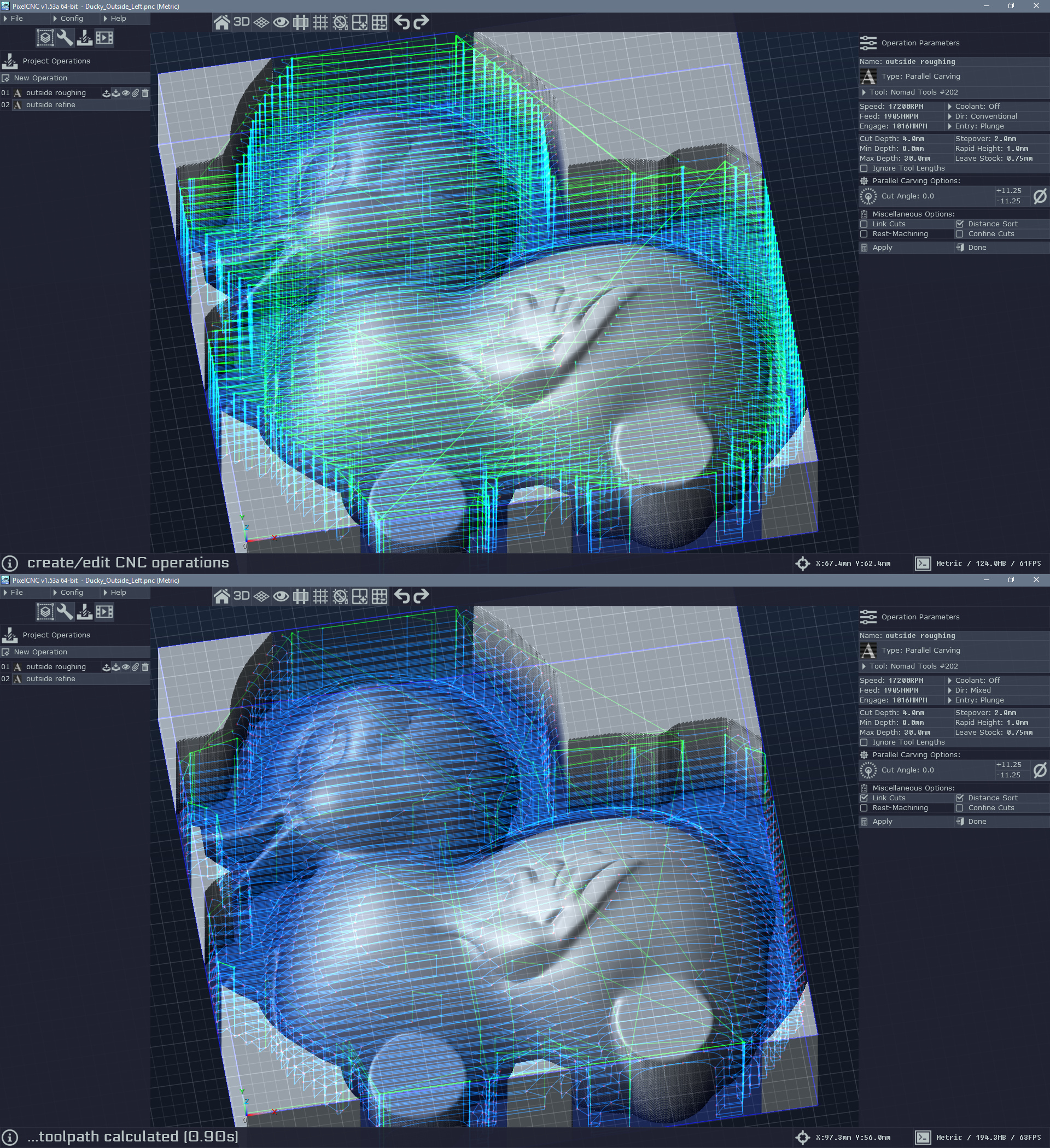

So the first major thing is that your roughing operation, which is of the Parallel Carving type, was not using Link Cuts. This perhaps is an option that should just be removed entirely and permanently enabled because I can't really see why anybody would want it off :P

The next change was to go from a conventional milling toolpath type to mixed, allowing the cutter to change directions - which with a roughing operation isn't as big of a deal as when finishing where a machine can flex or the cutter can not produce as good of a finish when cutting one way vs the other.

This greatly reduces the number of rapids, and the overal rapid distance which in the simulation mode shows that we reduced them from 35 meters of total rapid travel down to just under 4 meters! The current public build of PixelCNC, v1.53a, does not include rapids in the estimated runtime readout (this has been changed for the next release, which includes machine max and acceleration settings to properly calculate rapid travel times).

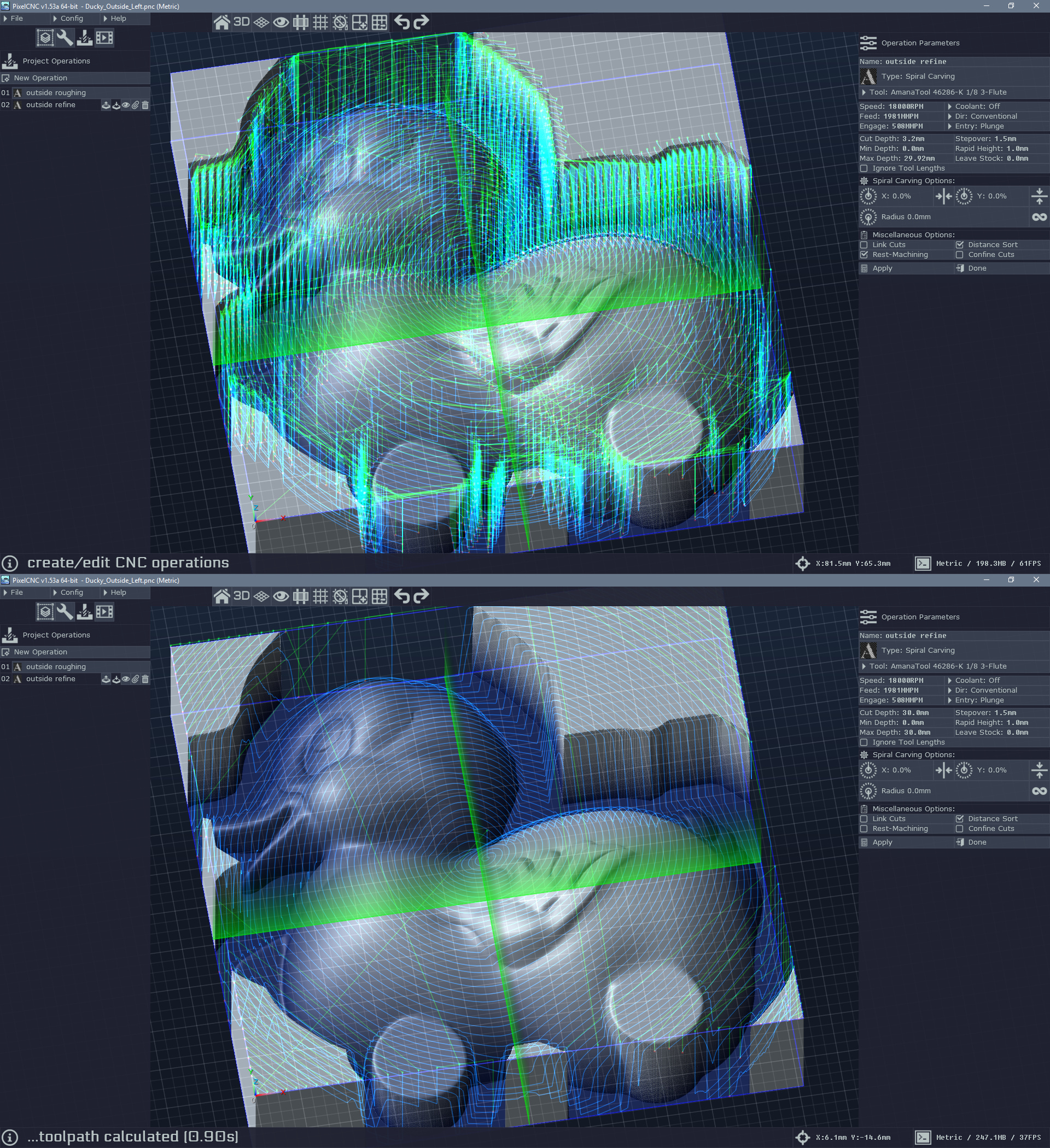

Next, for the cleanup/finishing operation, which is a Spiral Carving type, we can just cut at the full depth now that the roughing operation should've removed the majority of the material that's in the way, rather than at 3.2mm depth increments. The project is 30mm deep but the cutter being used (the 1/8" tapered ballnose) only has a 25.4mm (1 inch) flute length. As I mentioned earlier v1.53a has a bug in its Ignore Tool Lengths option in an operation's parameters (this has been fixed for the next release) so to make sure we can use a 30mm Cut Depth we can just cheat a little and edit the tool's definition to have a 1.25" flute length:

Now we can set the Cut Depth and Max Depth to 30mm. In the next release this little "hack" isn't necessary, and users will be able to just use the Ignore Tool Lengths to let their cutter reach the full depth of their project - just make sure material has been properly roughed out beforehand!

We can also disable Rest Machining now that we're just going to be cutting all the way down and following the canvas surface.

Here's the before/after:

Once again we have a lot less rapids now! In fact, I would hazard saying that you can do away with the mask around the ducky and just let the machine cut everything out now because it will be significantly faster than before, even while removing that material in the corners :)

According to the simulation we've reduced the total rapid travel for the operation from just over 49 meters to ~2.5 meters.

Hope this helps! ;)

Charlie