Hey all,

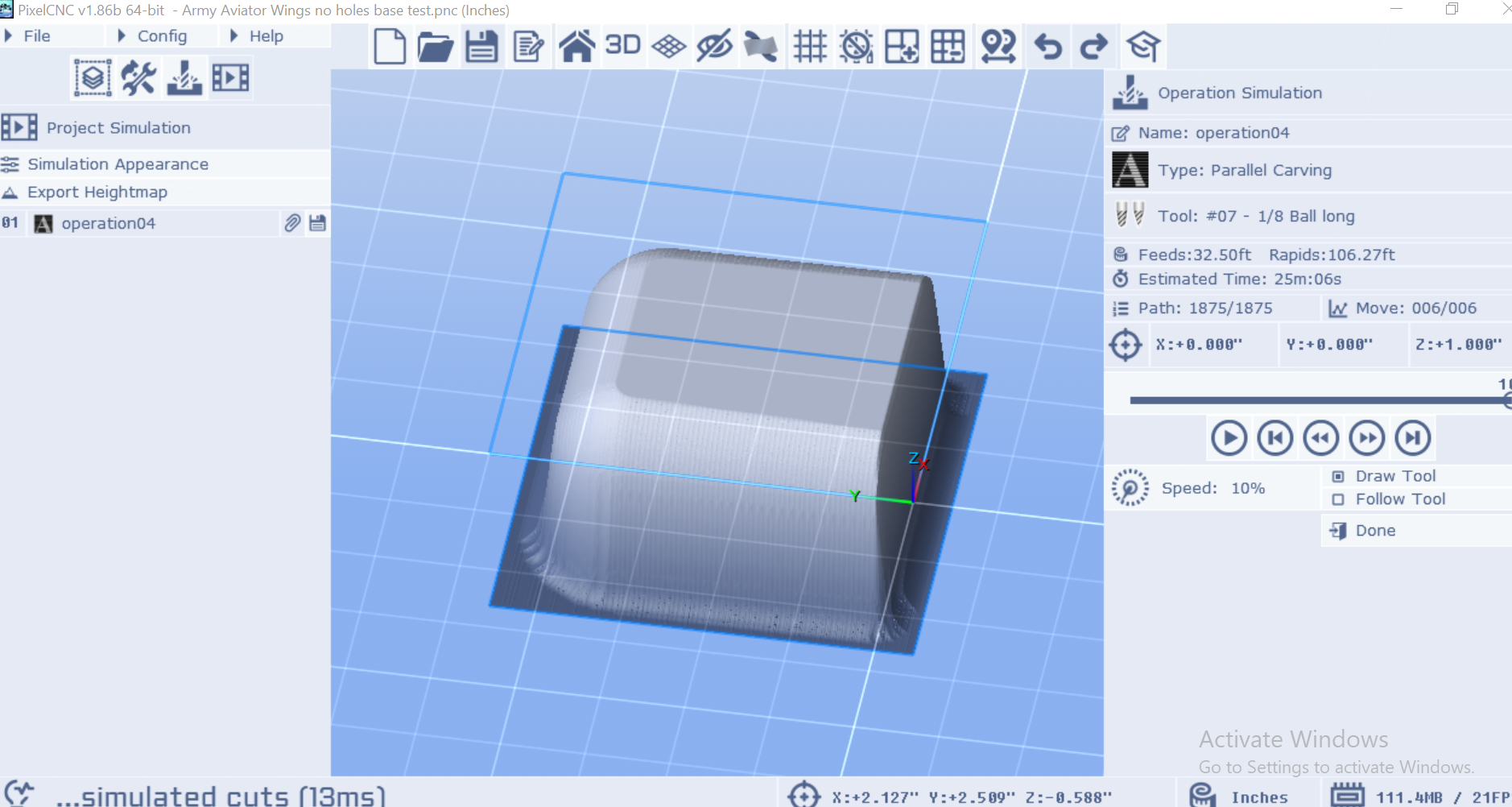

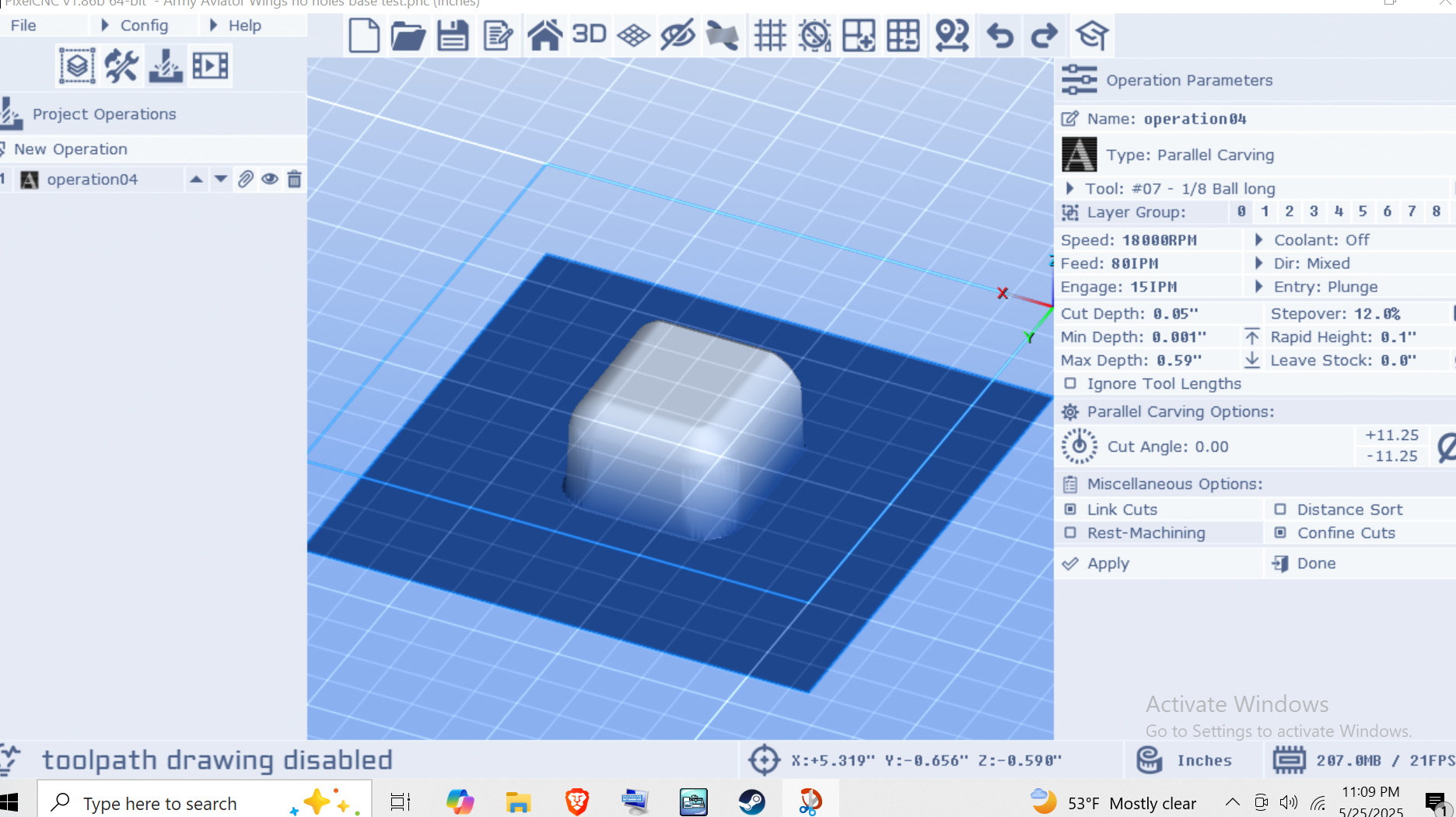

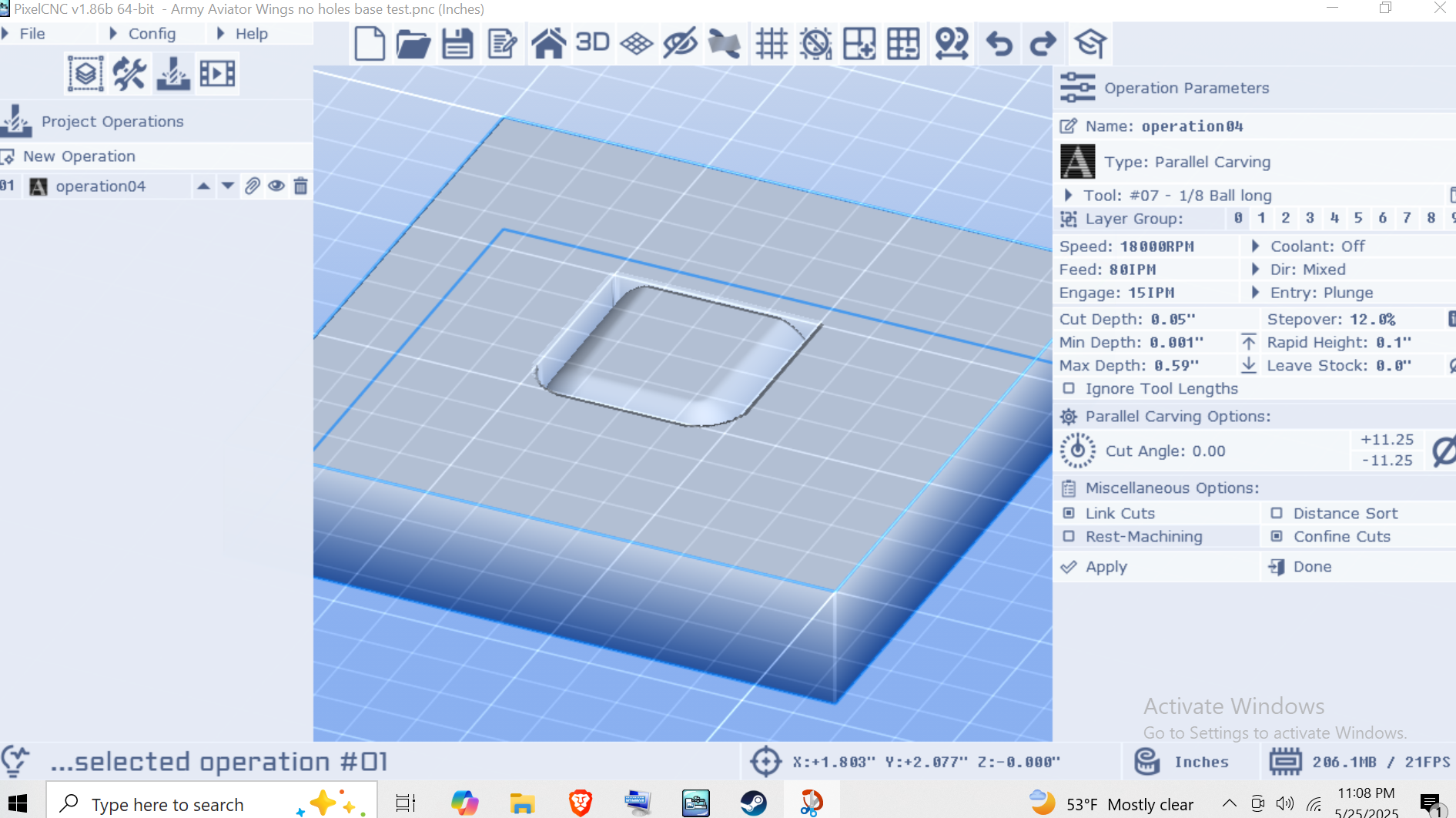

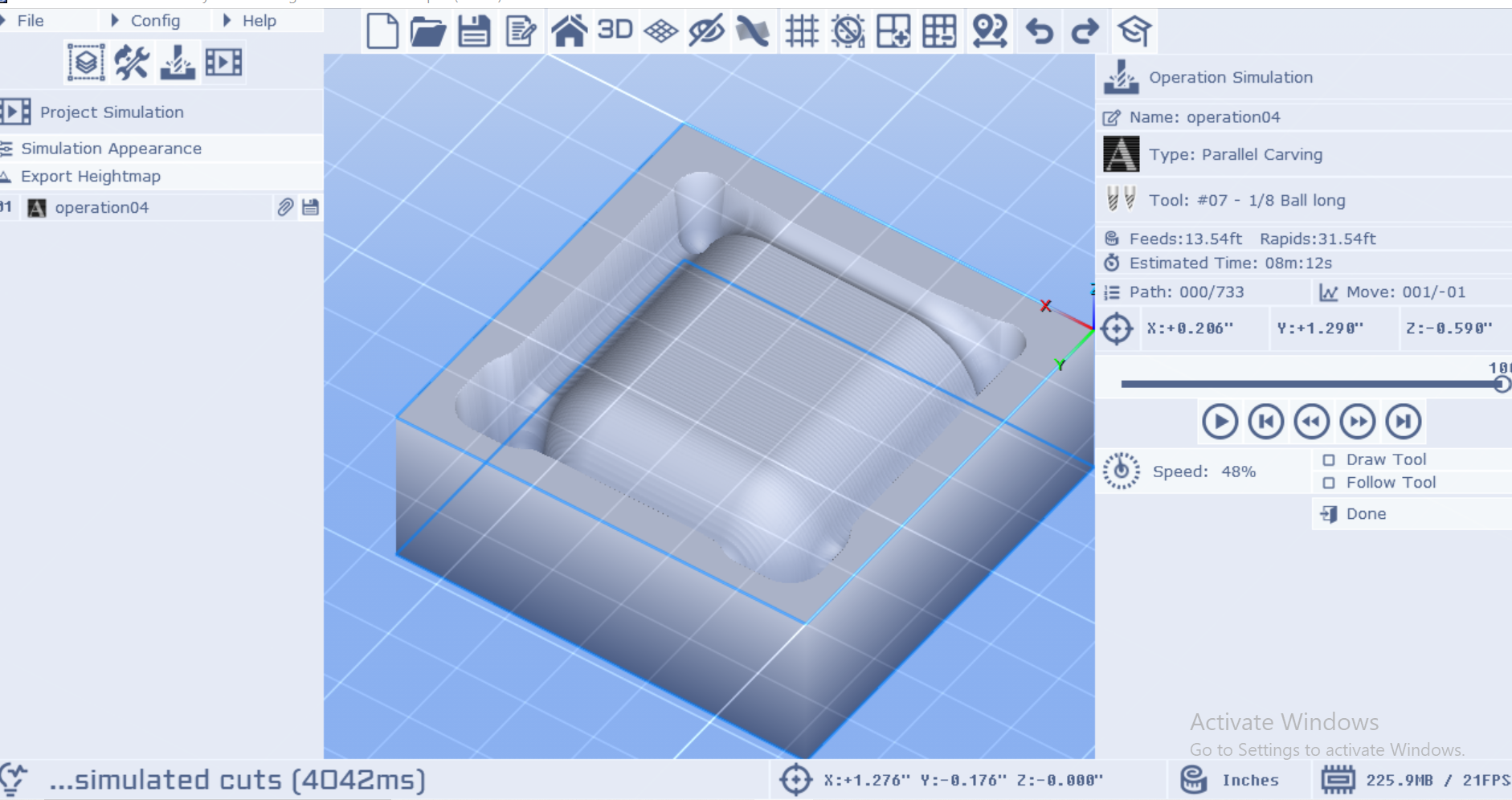

Got another issue, I'm carving an STL with .25 radius along a few edges. Normally when I do a parallel carve on an STL I use Z fill or it will try to cut the entire board instead of just the model, however in this instance it doesn't want to cut the whole radius. I tested a small 1.25x1.25 piece with no Z fill, ie cutting down the "whole" canvas and the radii came out just fine. So how can I fix this? I feel like I'm just missing a step or an easy fix.

Thanks in advance

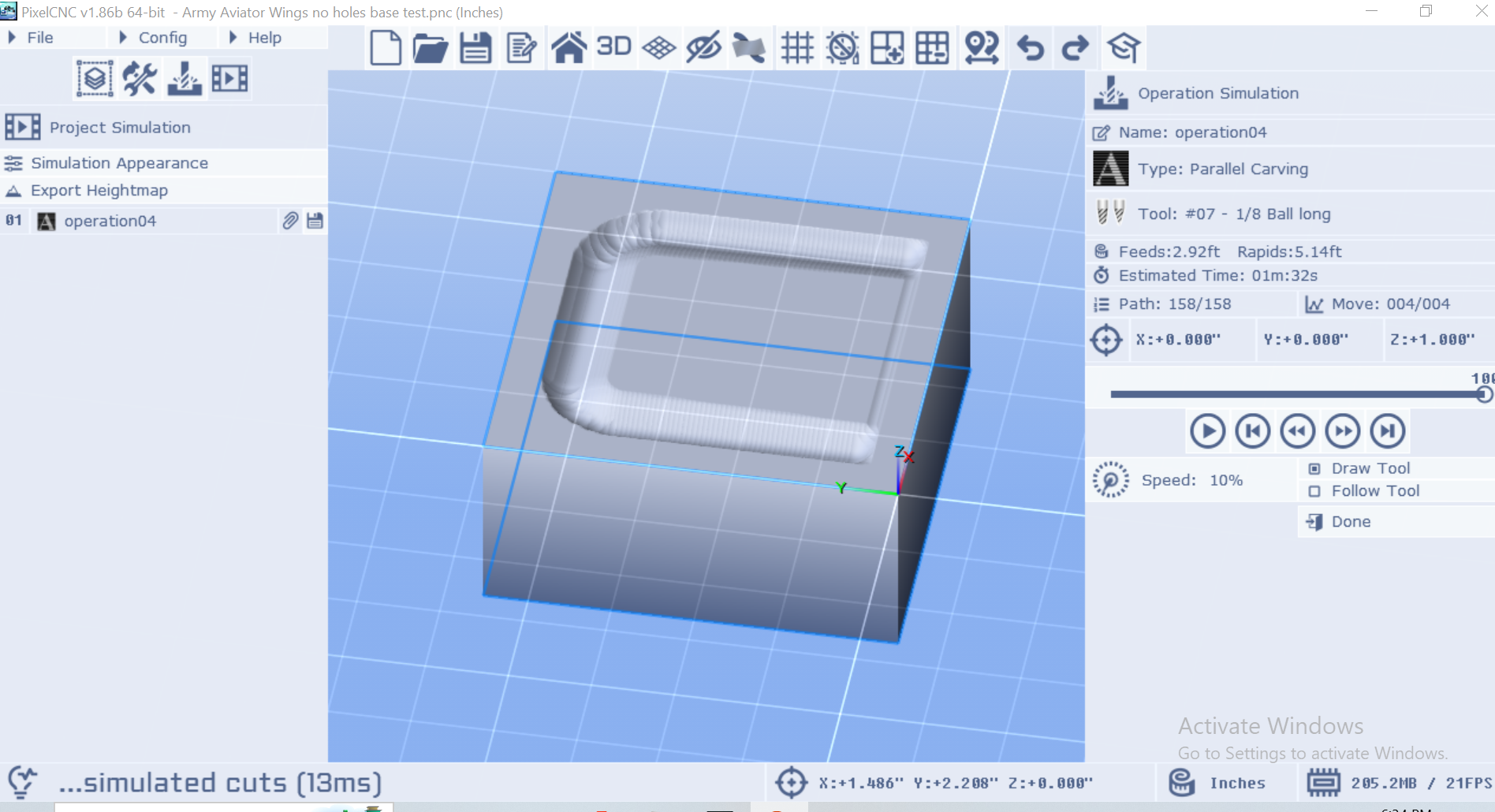

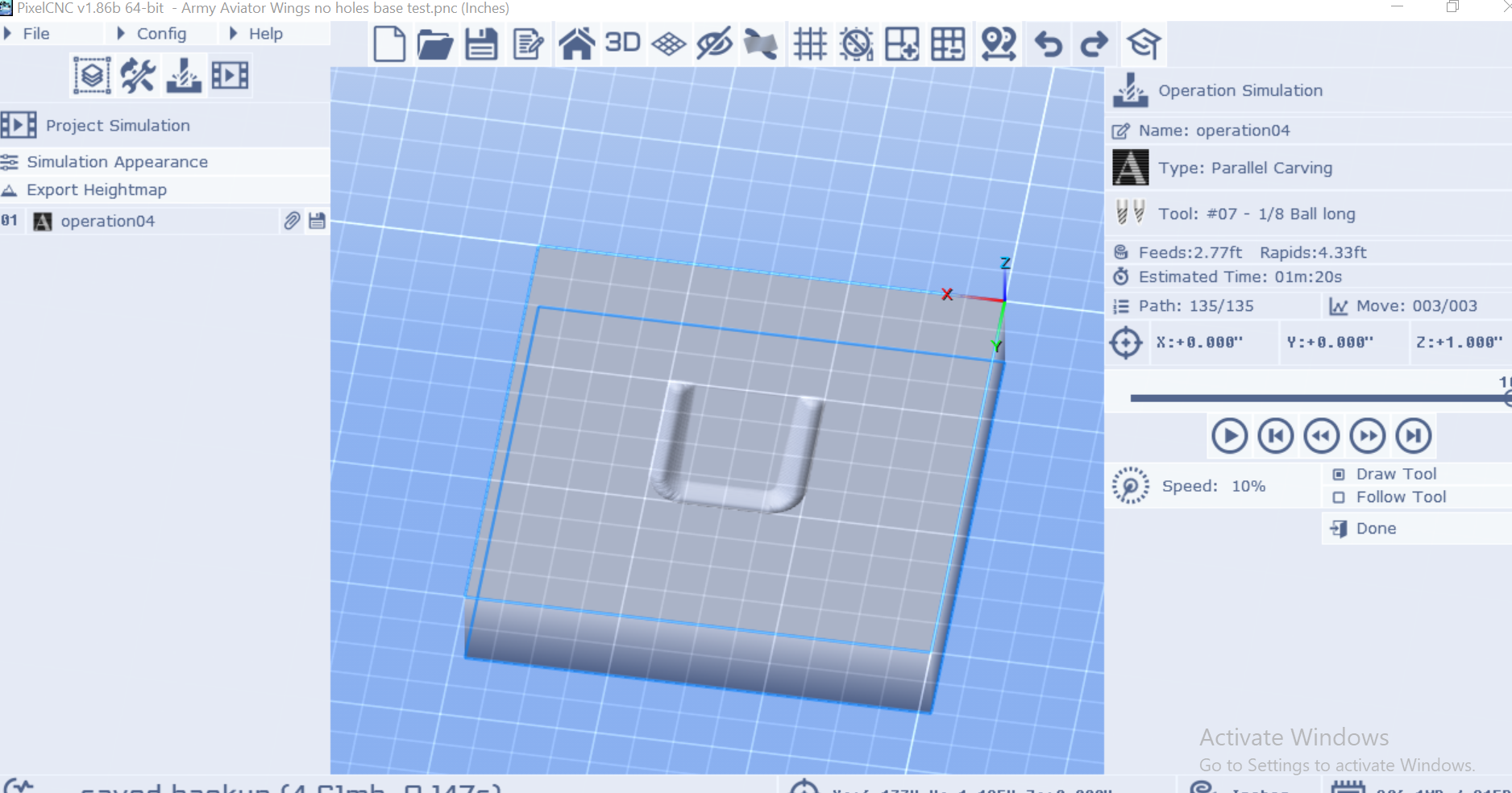

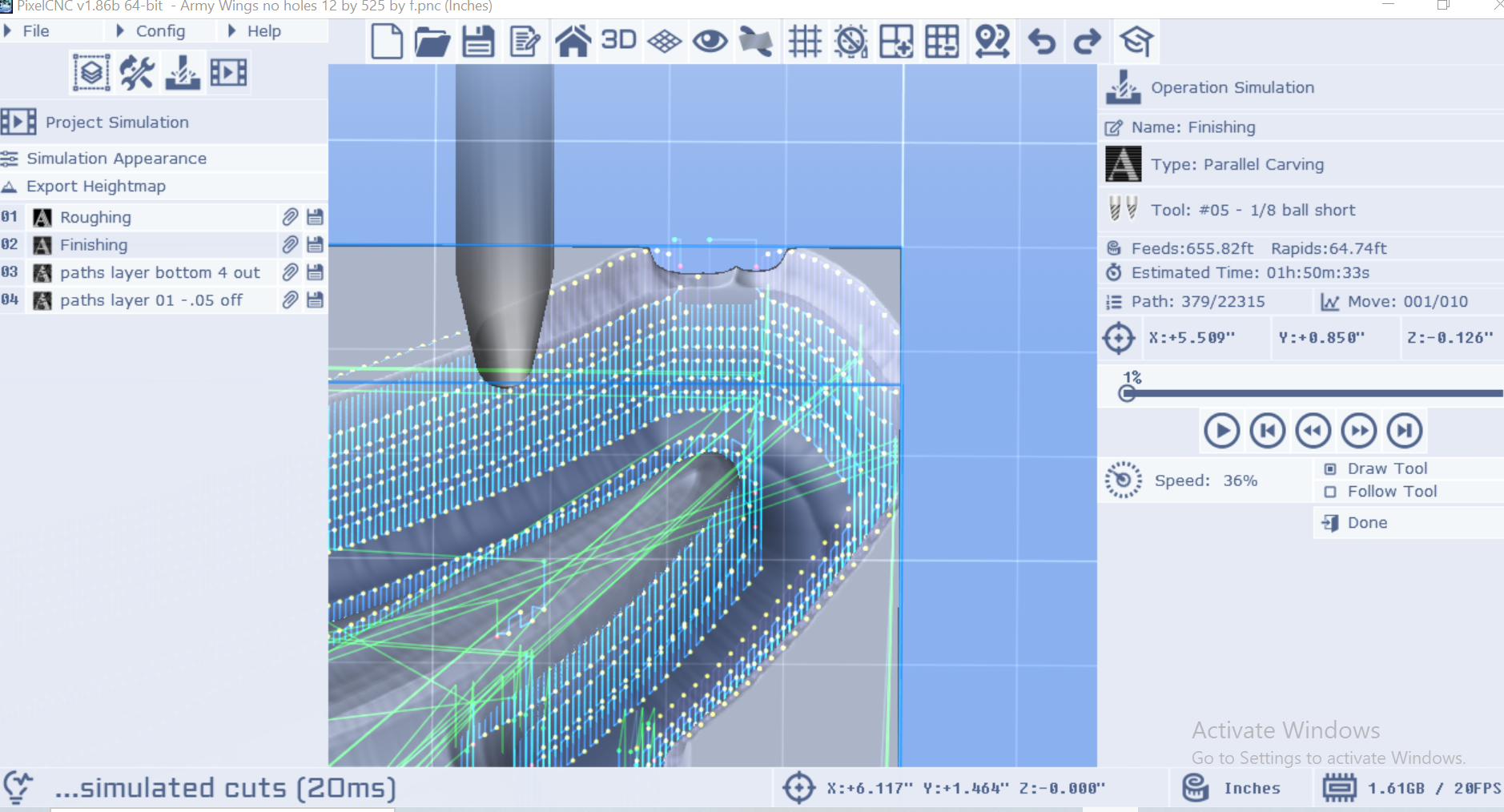

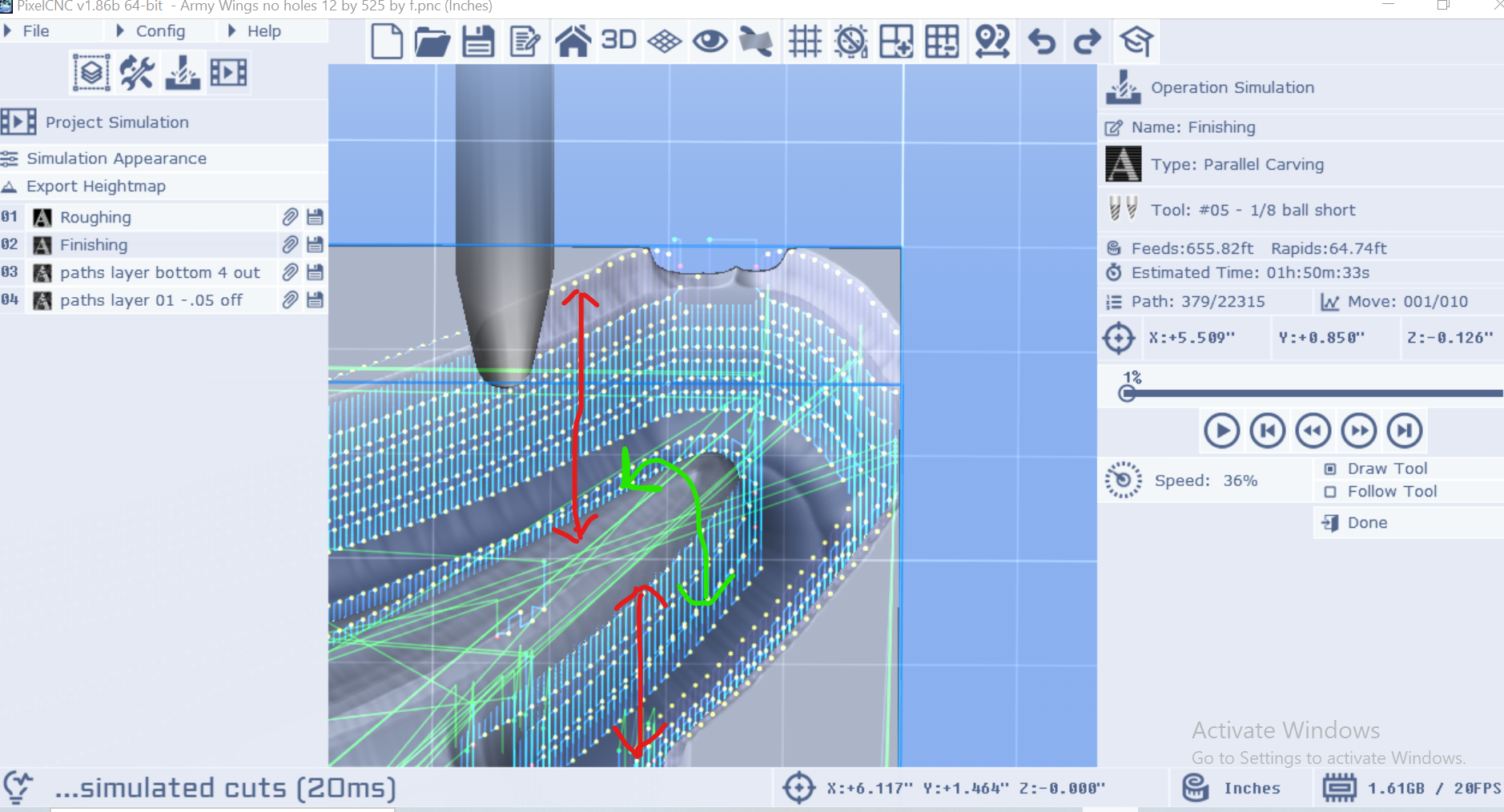

After the roughing pass there is no material near the model that would need to be cut away to make room for a bit but the finishing pass still insists on touching the outer wall of the raster layer. Is there any way to stop this or is that just the way it is?

After the roughing pass there is no material near the model that would need to be cut away to make room for a bit but the finishing pass still insists on touching the outer wall of the raster layer. Is there any way to stop this or is that just the way it is?  It's doing the red arrows when it really only needs to be doing the green arrow. Hope that makes sense, looking forward to hearing your thoughts

It's doing the red arrows when it really only needs to be doing the green arrow. Hope that makes sense, looking forward to hearing your thoughts