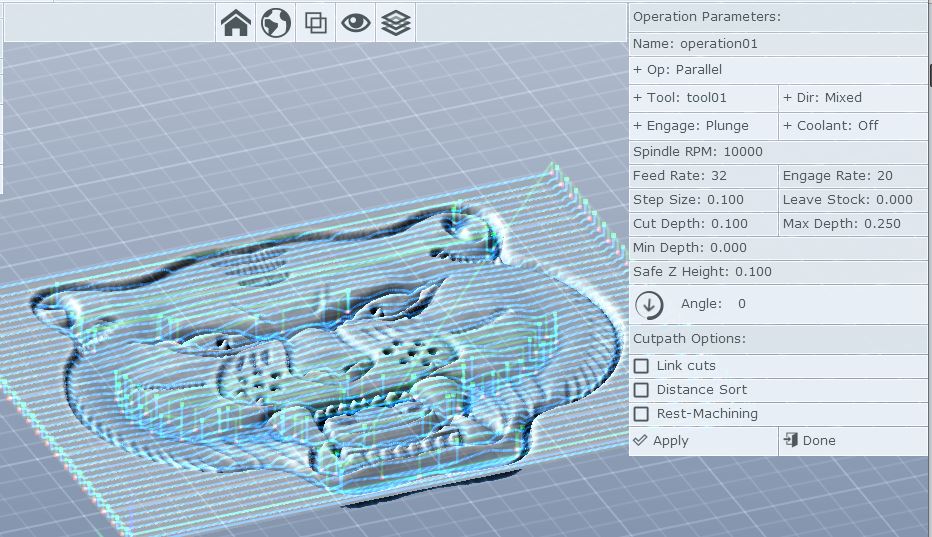

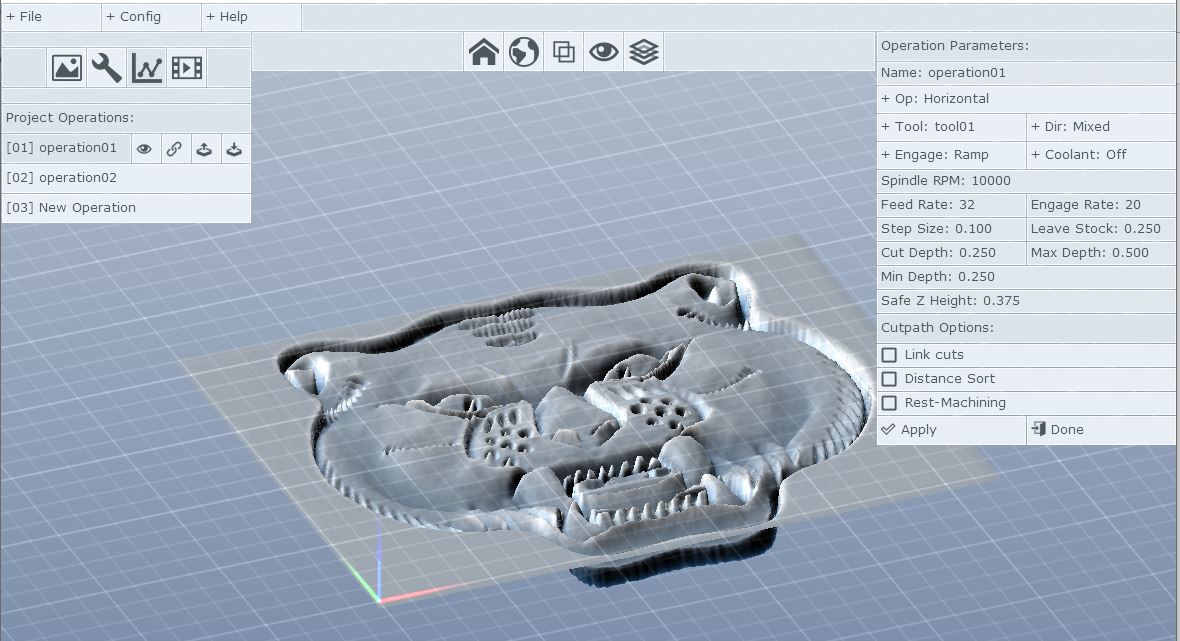

Hi, I have been dark for a while rebuilding my DIY CNC... I returned to learn of a recent release. After importing my Tiger image, creating two tools (BYW, it would be nice if there were a way to catalog tools permanently), I am not getting the results expected creating tool paths. I have also gone from inches to metric back to inches (I don't know if there is any persistence kept for some values?). Any way, I've left and created a new project, and this is my tool path screen...

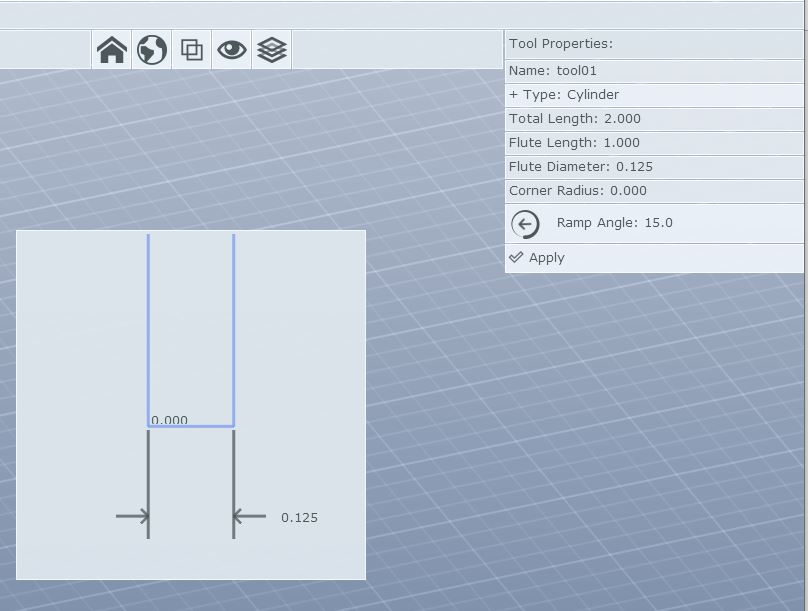

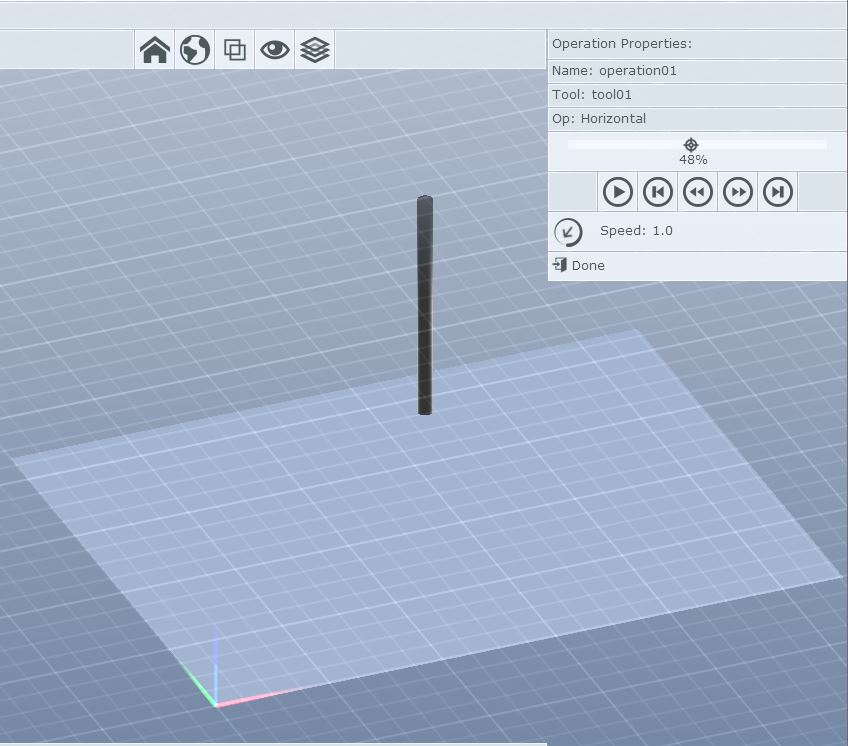

My Flat milling tool below...

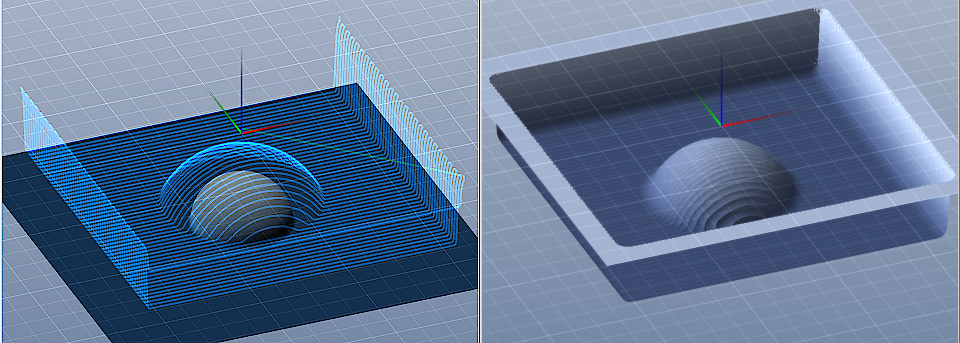

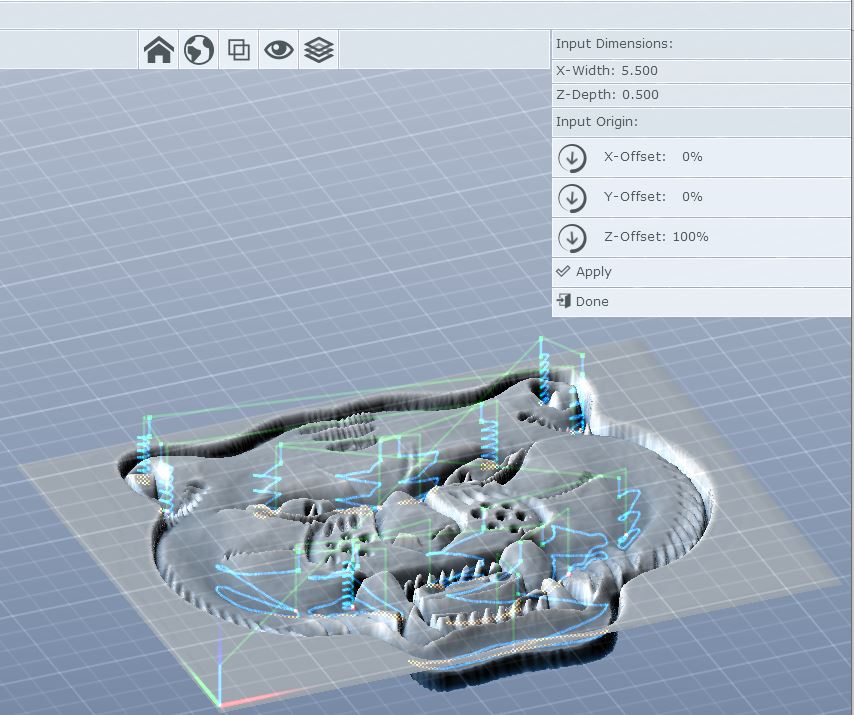

My image below...

There is nothing to simulate?

When clicking generate G-Code the program abruptly disappears without a message... What stupid thing am I doing wrong?

Thank you,