Hello, I have a question as to whether PixelCNC would be a good match for my use case.

Background - I have some miscellaneous small objects such as seashells, crystal clusters, and fossils that I'd like to mount on custom bases, preferably clear acrylic.

Proposed Method - The idea is to use a 3d scanner that generates a model. The scanner gets a point cloud, then builds a mesh, and the software exports an STL file. Using OpenSCAD operations, the model is rotated, truncated, then a relief on a rectangular base obtains the model of the custom base. I scaled the base up in all dimensions by 5% to allow for a bit of space when the object is put onto the base. This workflow was validated (so far) on an FDM printer. The 3d printer got satisfactory results -- the bases are fine, though the material (PLA) is not what I ultimately would like to use.

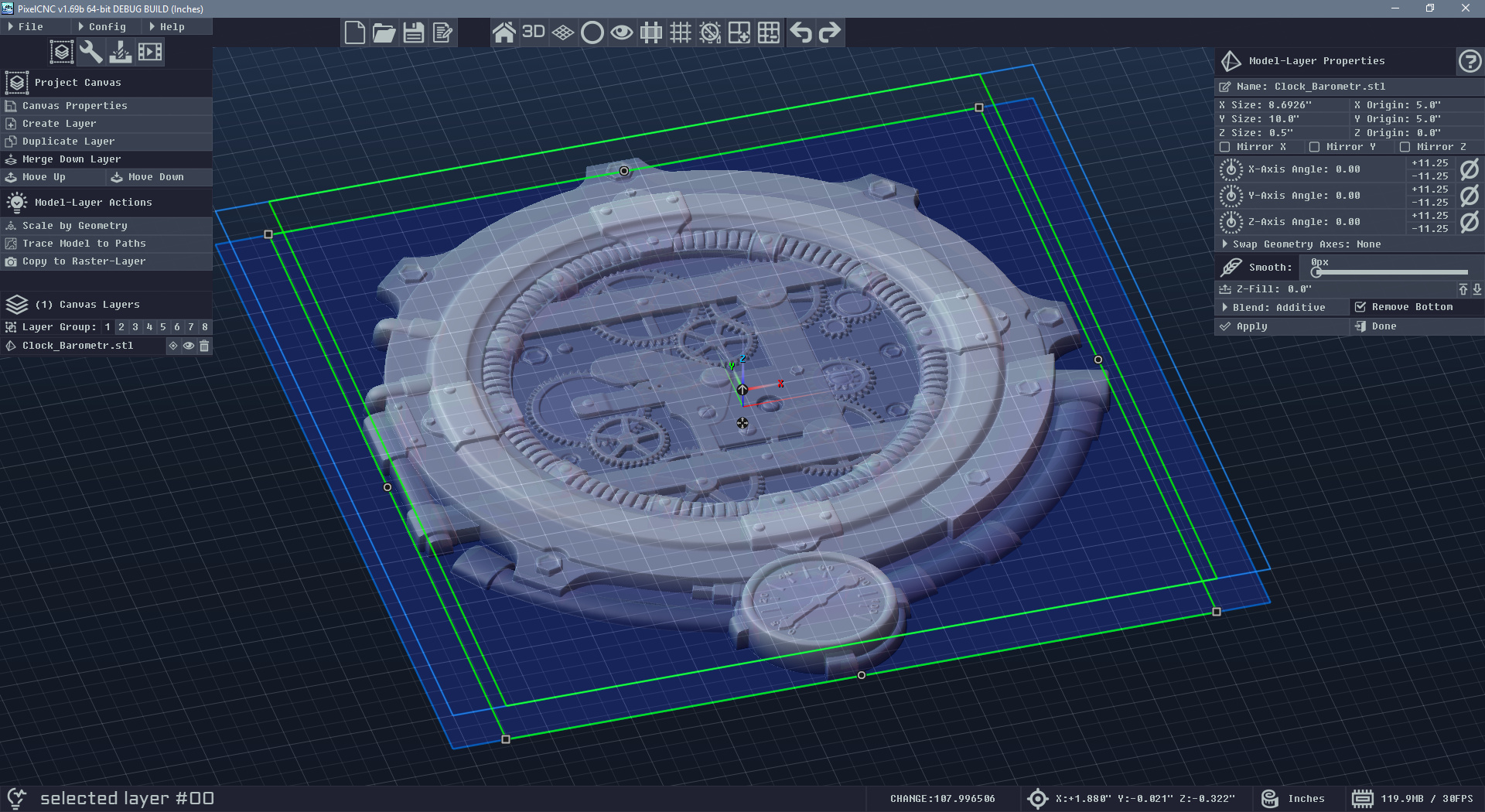

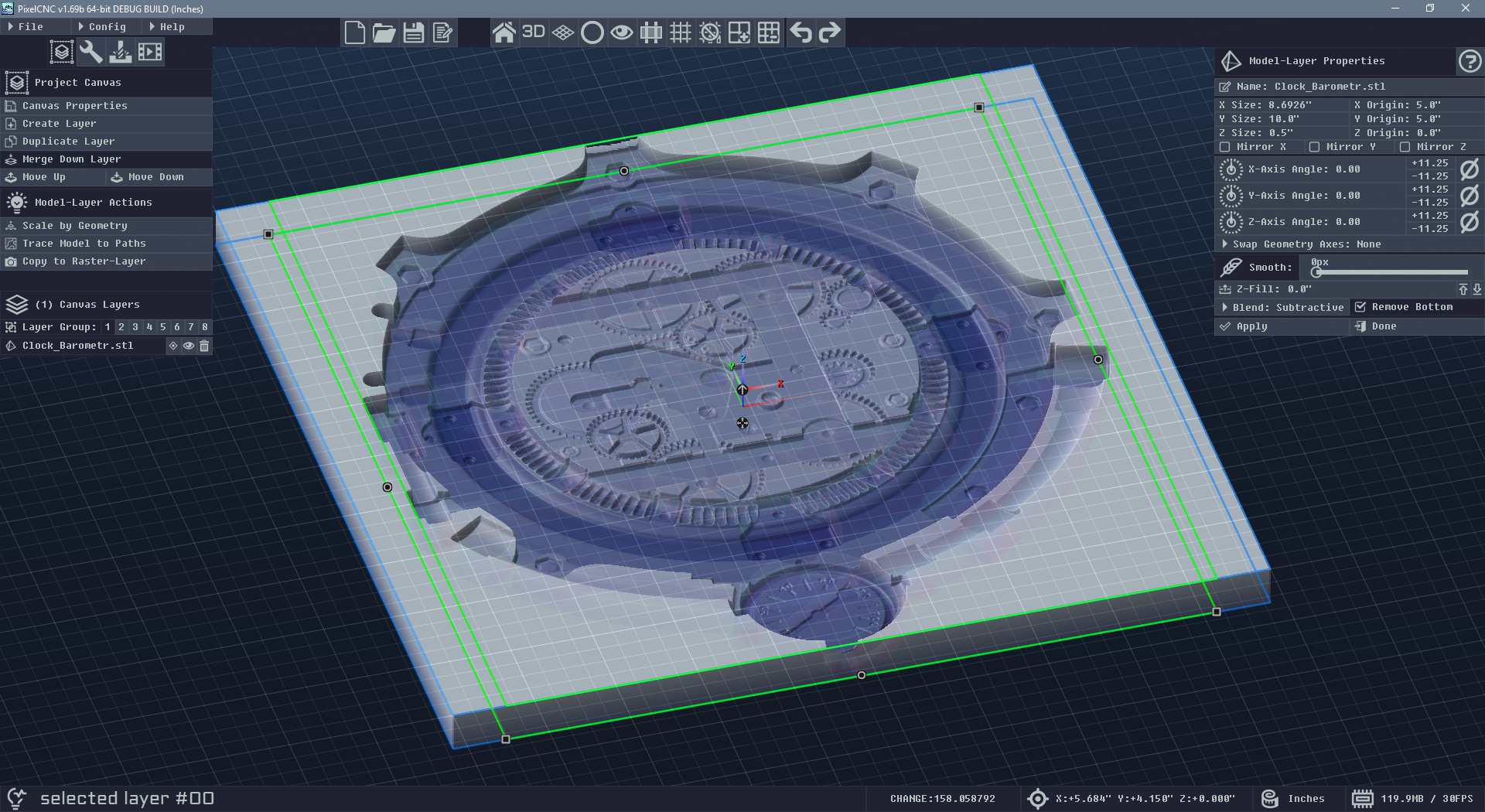

Question - Can the last step of the method, using a 3d printer, be replaced by CNC on acrylic? PixelCNC could import an STL generated from the OpenSCAD model, then carve a relief onto an acrylic block. One concern is keeping faithful to the dimensions so that the object will fit well. I saw from the first tutorial that you can size the canvas. Would it be enough to measure the acrylic block and then size the canvas to its measurement? Any advice on whether this plan is reasonable?