Milling operations did not save name between projects.

CAM software developed by artists for artists to create unique and original works on a 3-axis CNC router or mill. · By

Hi Charlie!

Have noticed that i cant seem to load raster images from folders containing letters like ÅÄÖ.. same file will load without problem from any folder not containing these letters. No issue to load stl files from these kind of exotic folders tho.. Didnt see this bug in issue or fix list, so thought i mention it..

Did however see that youre planning on adding adaptive toolpaths, sounds crazy brilliant!

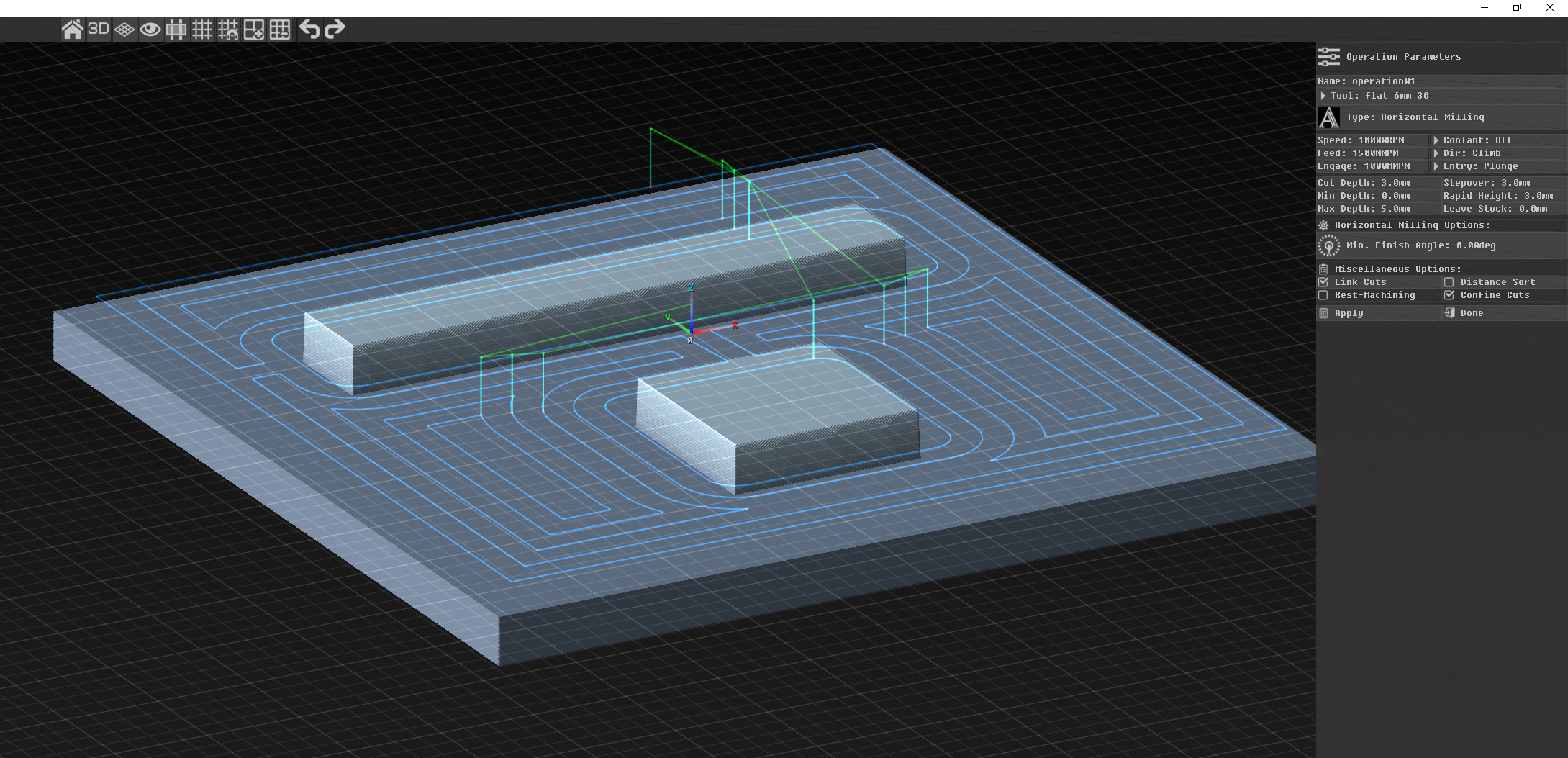

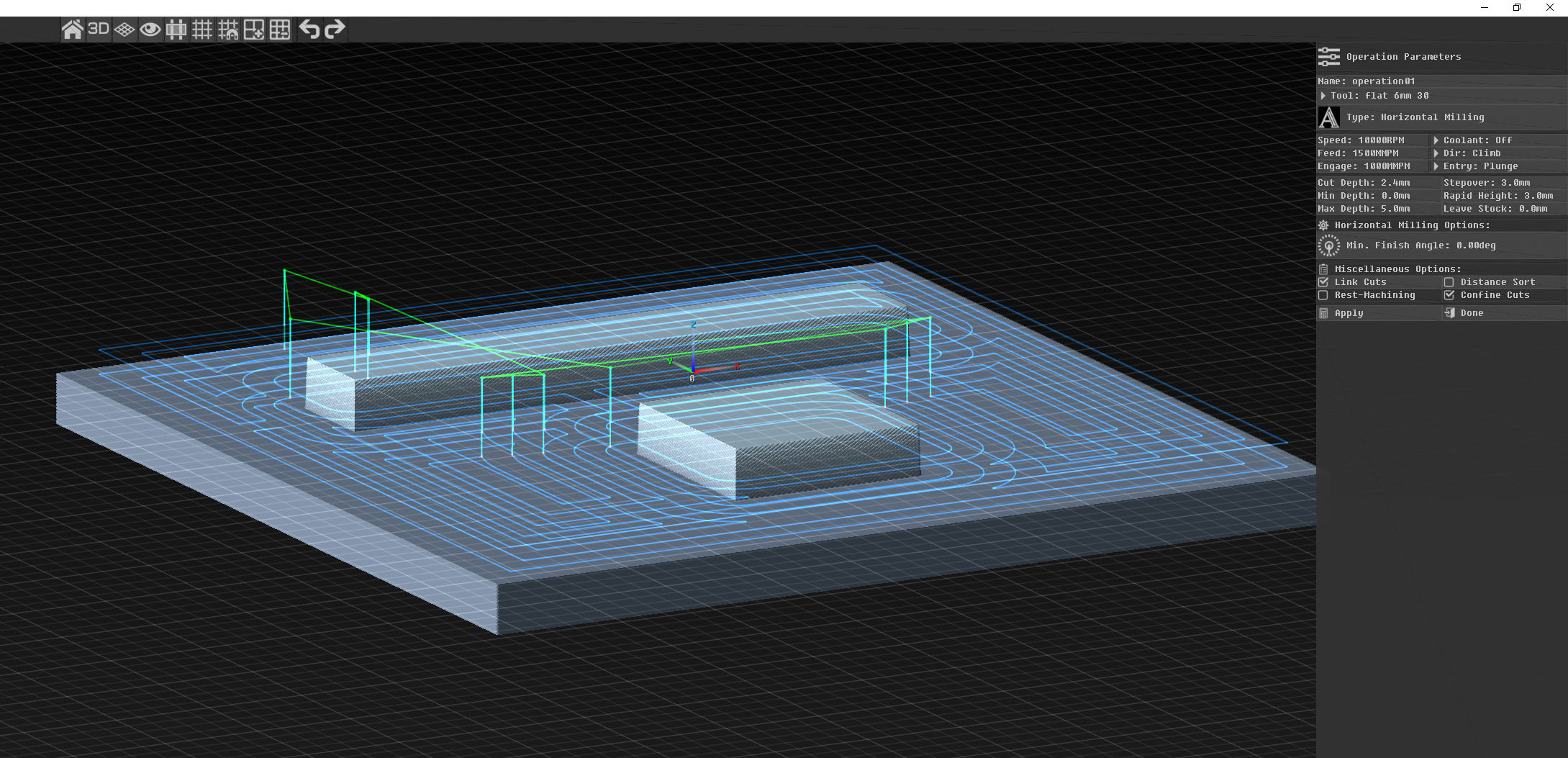

Have encounterd some minor problems while playing around with horizontal toolpaths where maybe sharp edges in stl files seem to create a micro height not allowing the toolpath to reach all the way down. (Im guessing that 3d objects gets converted to raster image and thats how the toolpaths are then calculated and the contrast is what gives these not perfect sharp edges resulting in not a 100% flat surface. Did test around using 9 samples and no smoothing 500dpi) No big issue when a pocket operation with max depth to the "floor" could fix this particualr issue in some cases atleast. Did however have som wierd results with a cut depth of 3mm where it left 2mm uncut, leave stock set to 0, (total depth was exactly 5mm in the model). 2.5mm left 2.5 mm of stock and 2.4 did another pass and left 0.2mm of stock.. Maybe it only goes for whole "cut depths" where they fit, but that would render stock to leave option kind of not so trustworthy? Especially if the depth of cut is somewhat significant in depth, see attached picture. Now im on thin ice but another more complicated model looked really good after playing around with horizontal not paying too much attention to how much stock was left or if it only used the whole cut depth. Anyway im super impressed with how it all works, how fast it is and very much looking forward to whats to come!

BTW. Did cnc this test piece and tolerances were spot on! :)

Cheers! /Xalor

Hi Xalor,

Sorry to be getting back to you at such a late date! I didn't receive any notifications that you'd replied to this topic and it was pure chance I stumbled across it just now, doh! I'll have to keep my eye on the forum more closely. Yes, the horizontal milling toolpath simply generates cuts at "Cut Depth" increments until "Max Depth". While there's no guarantee that a pocket is flat at the bottom, and therefore no way to back up the cut depth to the bottom of an arbitrary pocket's bottom (because there's nothing requiring the pocket to be flat at the bottom) it just contours at successive depths.

The "Leave Stock" parameter offsets the canvas outward in all directions, both horizontally and vertically. It's effectively doing the same thing that the raster-layer editing mode's Expand/Contract function does, but "behind the scenes". This means that a pocket 6mm deep with a leave stock of 1mm when horizontal milling will become a 5mm deep pocket where a cut depth of 2mm will only produce two layers of cuts at -2mm and -4mm because there's no way to know where the bottom of the pocket is when there's not even a guarantee it will be flat. What you want to mill out very specific depths is the pocketing operation where you can directly control the depth it will cut down to, especially if you're looking for better tolerances. The horizontal milling operation is better suited for roughing out relief carvings and the like because it treats the canvas like a 3D surface whereas the Pocket Milling operation just contours it and then generates a set of cuts down to the specified Max Depth regardless of what the rest of the canvas below the contouring plane is like.

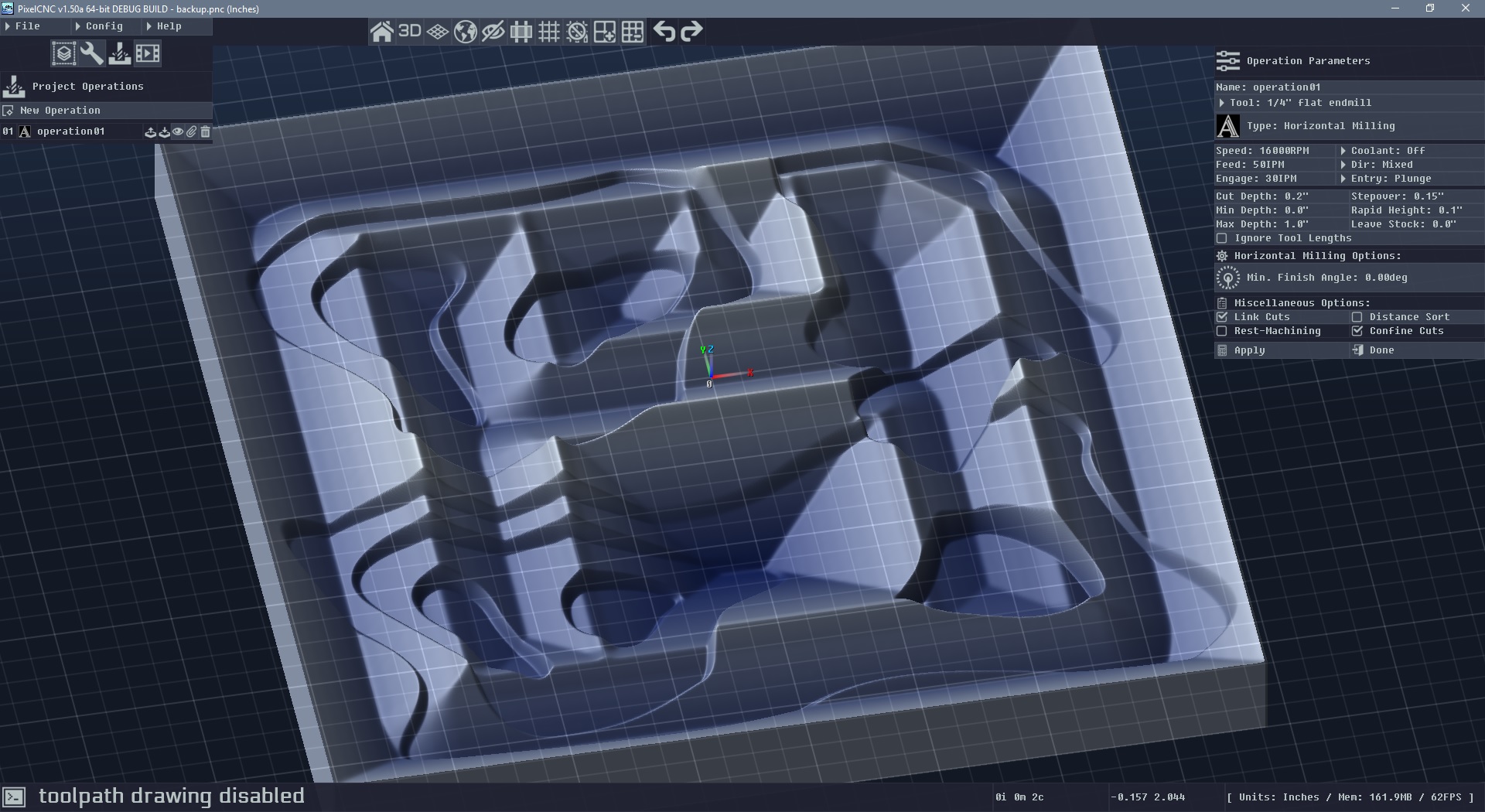

Here's an example of what a canvas could look like that the horizontal milling operation has to wrestle with:

I did just look at the code and while it does back up to Max Depth if a cut increment passes it there is an issue where even if a pocket reaches the bottom of the canvas there are no contours generated at the bottom of that pocket - which is a product of the contouring algorithm trying to contour at the same exact level as the bottom of the canvas - which is "solid" to it. I'll add in a fix there for v1.50a to make sure it is able to contour the bottom-most plane of pockets that reach the bottom of the canvas. Good catch!

v1.50a is just about ready. I've been wrestling with the blur/smudge raster-editing tools a lot more than I had planned - which is probably why I put them off for sooooo very long. It will be nice to finally have them out of the way. The next big thing I'd like to do is work on the adaptive/trochoidal horizontal milling, which I am unsure as to whether I should add it as an option to the existing horizontal milling operation or create an entirely new operation for. Either way is going to have its pros/cons for both users and me writing the code for it - it will be great to have though, especially for less rigid machines that struggle with cutter engagement varying all over the place, like my own machine does :P

Charlie