Hi,

I did it - I've made a decorated box to gift. It's about 220x90x90 mm in size.

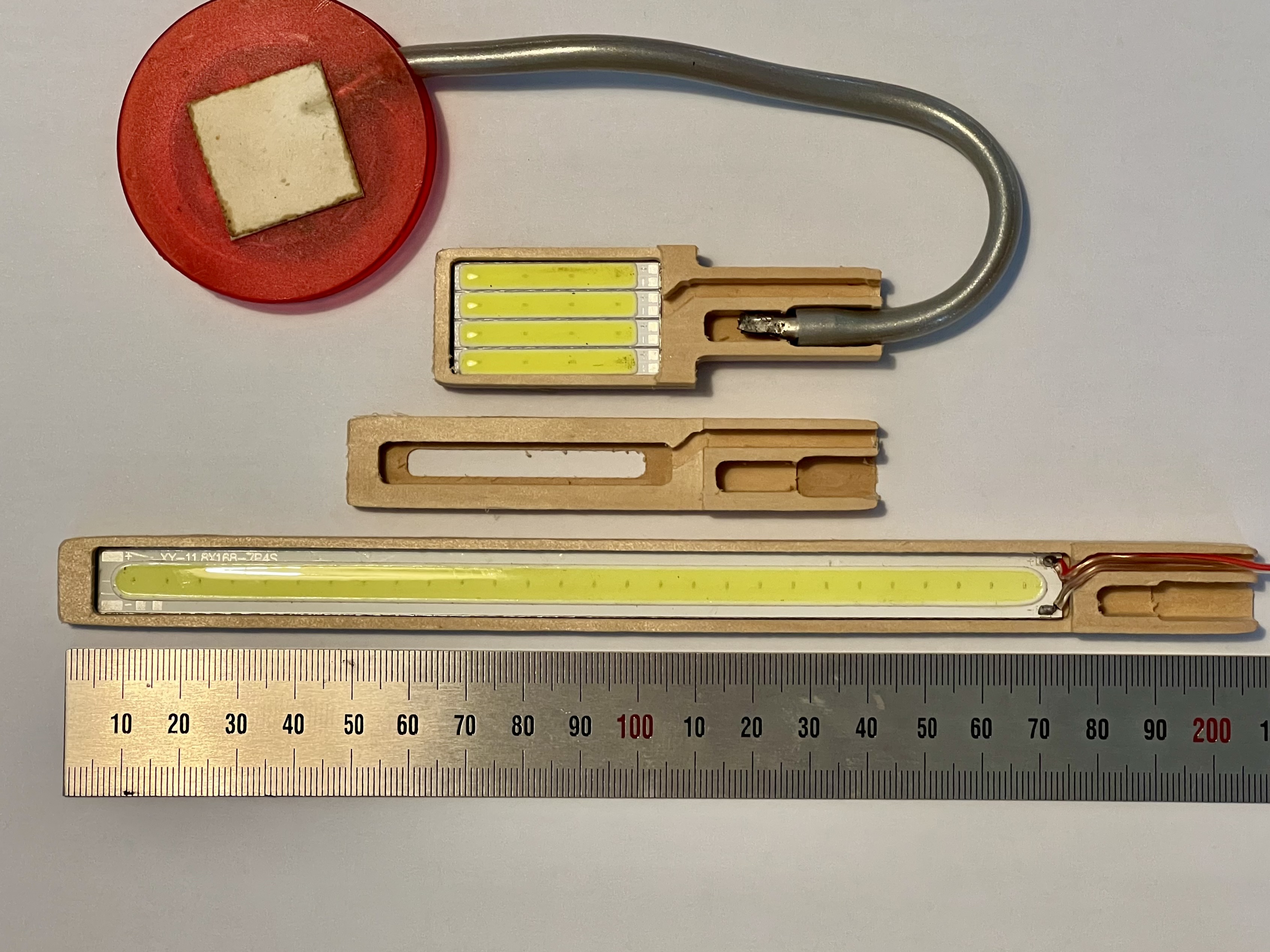

It's my latest challenge. This one is my prototype to test out the techniques of design and cutting solely using PixelCNC with 45 degree joints, wood inlays and epoxy inlays and doing double sided carves.

I have to do two boxes for my young grand daughters as a gift.

I'm surprised, so much came out great but it's the little imperfections that I need to work on eliminating. Also there's now big issue, I need to make the box wider.

To do this, as there's a limit to how many cut operations can be done, I've needed multiple PNC files to enable me to do the multitude of path cutting and pocketing needed.

Getting the double sided cuts were difficult in getting the alignments of sides accurate. Even though I had screw positioning holes, there always seemed to be an error. Sure it was small, about it gave a 1/2 -1 millimetre over the length. Checking and checking improved that when screwing up.

My new boxes will be wider; about 120/130 mm.

This means I'm going to need to be very careful while editing the layers to be sure I've transposed the new dimensions across the multiple PNC files I needed to do all the cuts, on all of the sides and those including the lid and bottom panel.

The wood inlays worked well once I had got the cuts right.

The other graphics were done using epoxy. That works well and easier too.

This lid fits on using an interference fit. I do have magnets to install but so far not needed. I'm now thinking a hinged lid would be better and easier with less accurate cutting needed to get the various lips aligned. to the base.

The corners are 45 degree joints.