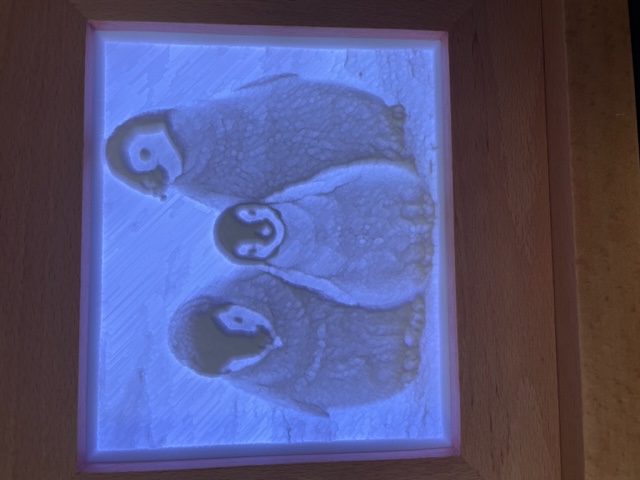

Latest Pixel CNC work - couple of lithophanes in 1/4inch Corian backlit with LEDs around a clear acrylic plate. First two photos are backlit, the second two not backlit

\56742198

]

CAM software developed by artists for artists to create unique and original works on a 3-axis CNC router or mill. · By

Hi Charlie,

Corian is the brand name for a solid surface counter top material made by Dupont. It comes in different colors and designs. I use the Glacier White as it is a solid white material. Apparently there are other similar products that works just as well - candlestone is one that I have seen referred to when researching Lithophanes. It cuts easily - I have used both 60 deg and 30 deg v-bits. I use a parallel carving operation at a 45 deg orientation with 0.0075 step over. With the 45 orientation I don't do a roughing pass. Doesn't make chips with that small of a step over but so far it has worked for me.

Doug

Reminds me of "cultured marble", which I thought was a funny way to try and hide the fact that it's just plastic :P

So no ballnose on the V-bits, you're just using a relatively small stepover? Is there any kind of manual cleanup after cutting - sanding or anything? They look really good, and detailed!

- Charlie

Hi Charlie,

Yes just a 30 or 60 deg v-bit. V-bit has is a true v-bit - no round over on the tip. On the penguins I used a 60 deg bit. On the portrait one I used a 30 deg bit as it had some cuts that had close to vertical sides. The 30 deg bit can go deeper when the cut has close to a vertical side. Yes very small stopover (0.0075 inches). The small step over means that even with the deepest cuts (0.20 inches) the bit is not overloaded as it is only taking off 0.0075 inches of material.

The only cleanup I do is to blow off the dust when I take it off the CNC.

I spend more time building the frame and LED light panel (3/8 acrylic surrounded by LED lights) that goes behind the carved panel. For a switch I use an RF remote control in the base.

In PixelCNC the canvas is at 200 ppi - maybe helps with the detail of the carving?? Still playing with PixelCNC settings.

Doug

The material is 1/4 inch thick with the deepest cut being 0.20. That leaves 0.05 of material for the deepest cuts which are the whitest part of the picture. The black part of the picture has no material removed with shades of grey in between. The imported raster image is inverted to get the correct depths in the model - white low and black high.

Doug