Hi,

I've stumbled on this bug on a current project, but was able to reduce it to the following minimum:

- Create a new Project, and create a new layer with the treeoflife3d.jpg file from the example images download

- Set the size to 50mm x 50mm x 10mm

- Introduce 2 tools: 4mm flat endmill, and 1mm ball endmill

- Create parallel machining operation with the 4mm endmill

- Create parallel machining operation with the 1mm endmill (with a 1mm cutting depth to force multiple passes)

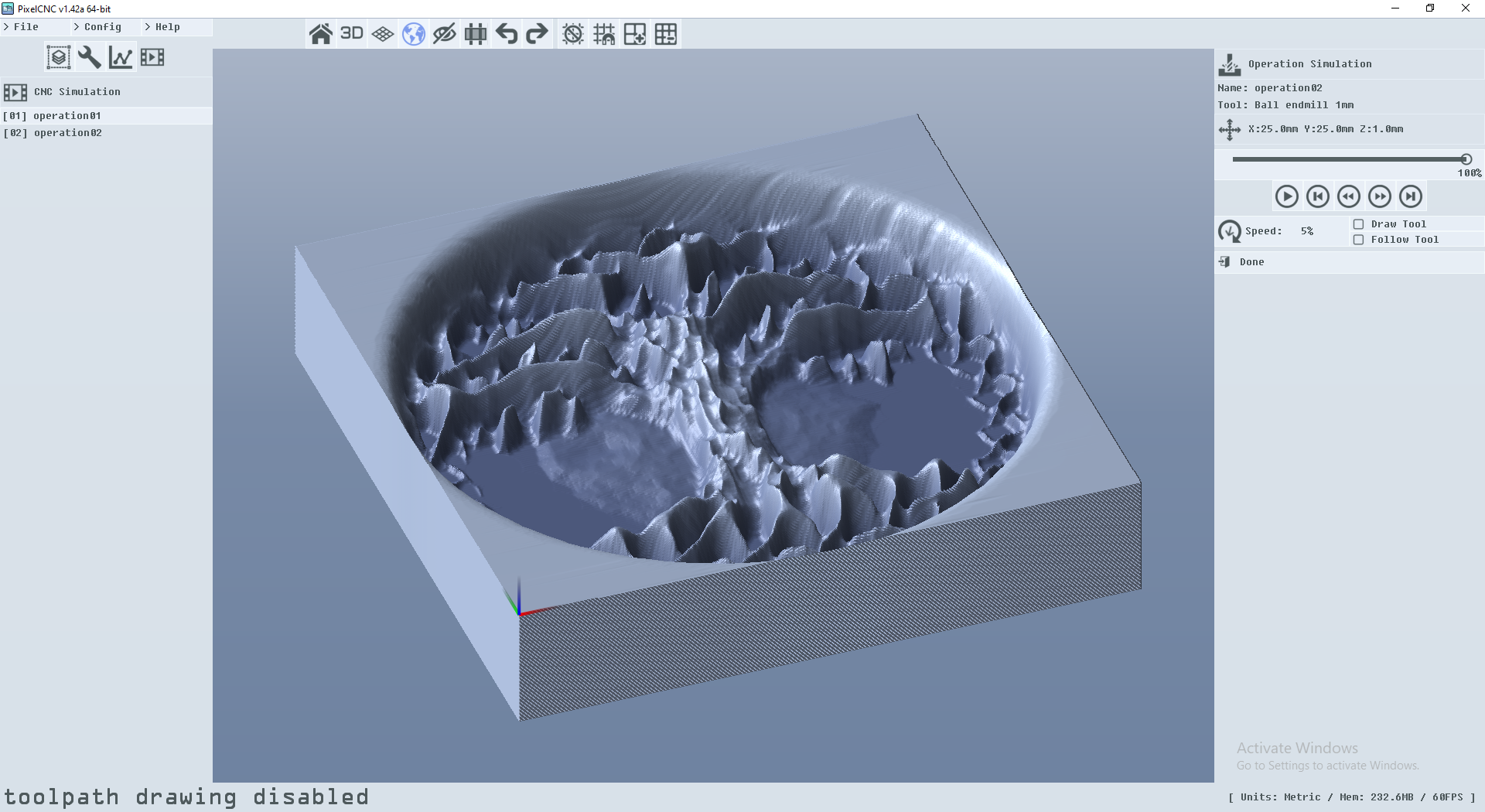

If the Operation in #5 is marked as "rest machining", this is the result:

If the operation in #5 is not marked as "rest machining", it works fine (meaning it produces the model created in the first step)

(Other parameters seemed to not influence the result; I looked at the tool paths in PixelCNC and in my CNC program to ensure this isn't a simulation/rendering issue - the toolpaths would create this result; Using the rendered versions above was the best way to visualise the issue)

Please let me know if more information is required to debug this, or is not reproducible with the steps provided.

thanks,

Mike