Hi

have a very similar question.

Are there any single line fonts compatible with pixelcnc?

More for smaller plates but something like

inkscape's hershey text.

Setup the machine again and recorded it this time.

Think I've found MY mess-up.

The calculator i used on my phone for feed rate doesnt have custom bit sizes. I put in i want 0.1 chipload but just looked and that's for a 3.175mm bit.

Found the calculator i used to use and it should be around 230mmpm not 2000 odd. Whoops!!

Video for fun:

Hi.

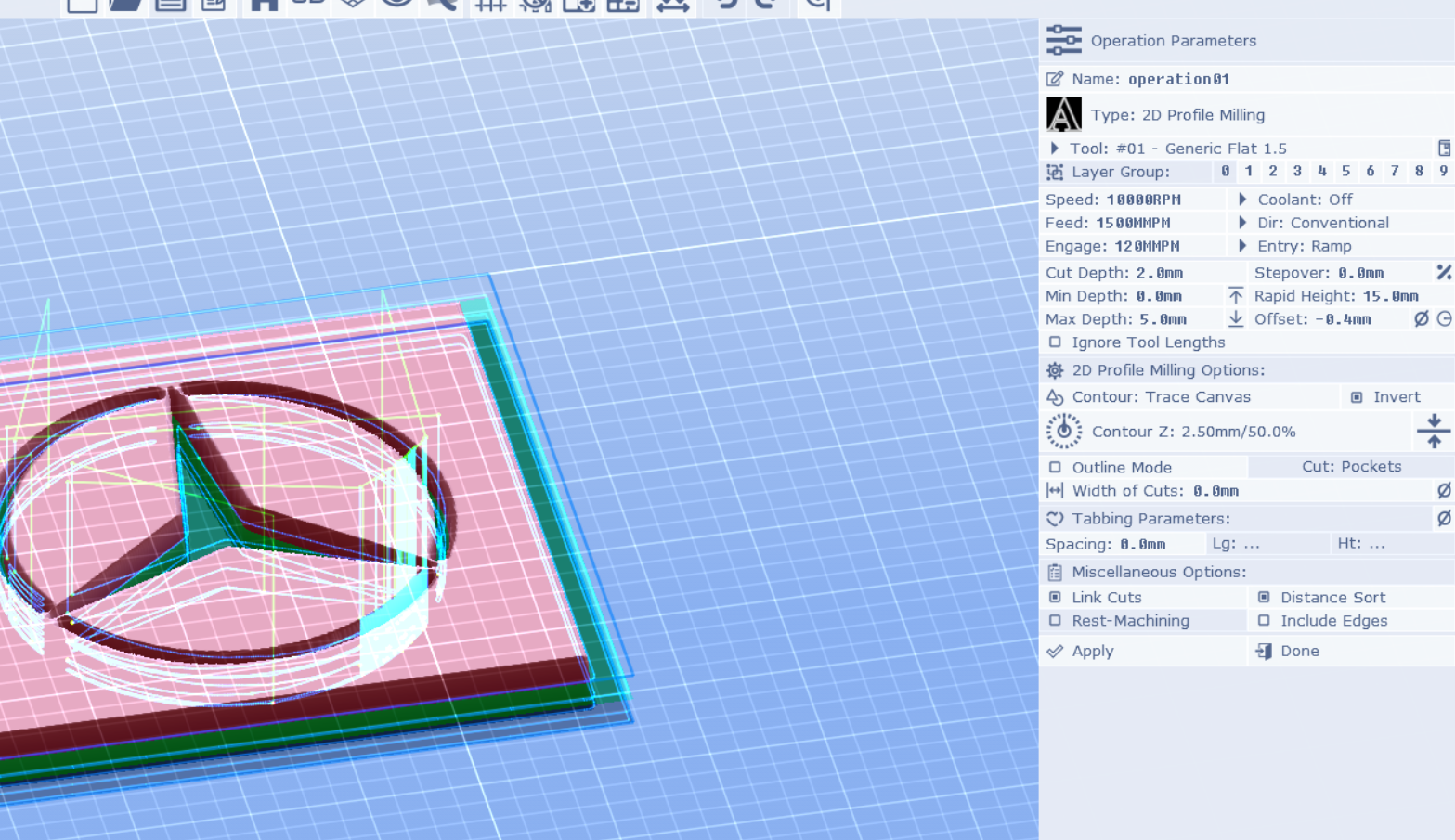

Been a while since i last used the machine but i cant get past the first rapid move when it should goto the safe height.

Every time it snaps the bit .

I've tried setting the rapid heigh to 15mm to try and exaggerate the move but it still snaps. It always seem to snap with the bit at max depth of the last cut before moving.

The preview doesn't play the move and skips from last cut to new location so assuming that is whats being output to gcode. no raise then move, just move.

Please help :)

Thanks

Hi.

Just thought I'd post a comparison of PixelCNC and another program*.

This is only my 2nd and 3rd model so still learning.

Same:

-Model, scaled down to same dimensions.

-Stopover and roughing cut depths

-Bits, 3.1mm roughing, 3.1mm finish pass, 0.5mm Tapered Ball finish pass.

The other programs version seemed a bit flat and difficult to see depth.

PixelCNC to me captures more detail and also seems to pop more.

This was only a quick test carve so i need to not do the 3.1mm finish pass to remove lines.

*not mentioning full name as I don't want to get anyone in trouble but with pics, you know :))

Hi.

New to the cnc world. Just trialling pixelcnc . It seems to be top so far!

I've added a image layer containing a greyscale depth map. All has imported OK and it has identified the 3d model.

What I would like to do after it has finished the piece is to then cutout the piece from the material.

Is there anyway to add a step to cut the perimeter?

Many thanks!!