Hi,

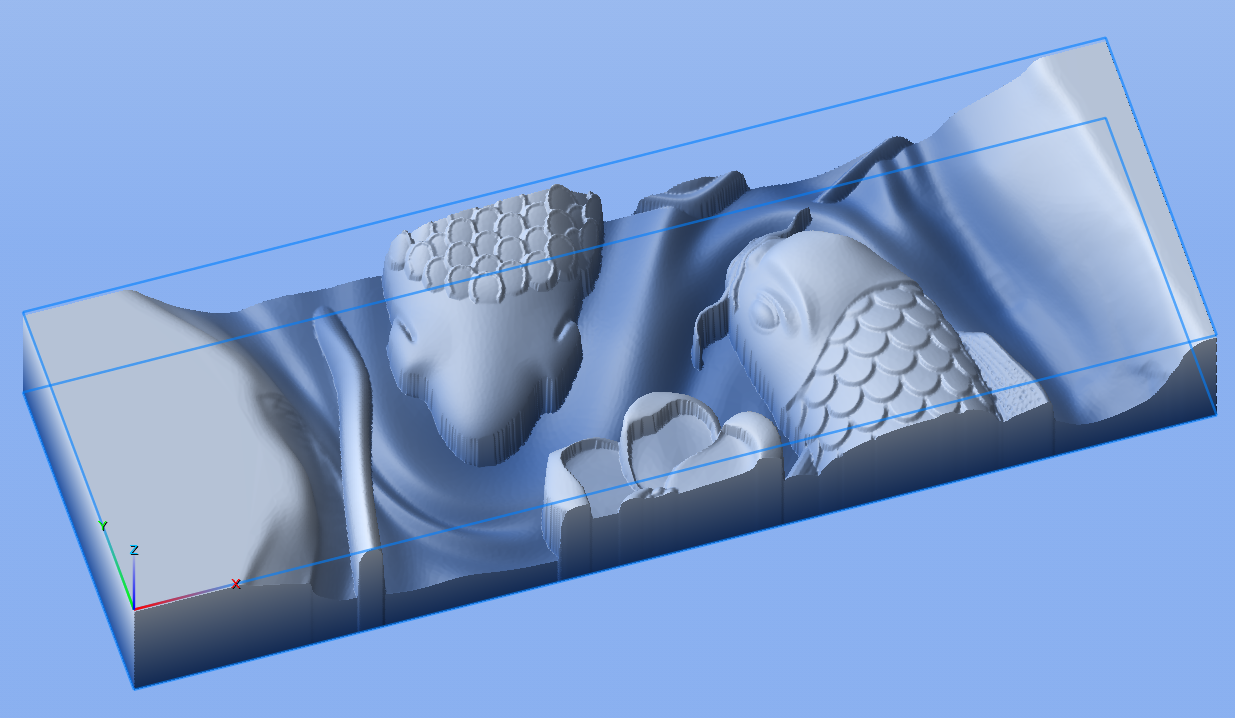

I'm new to CNC, and am trying to cut a relief. Here is an image of part of the model I'm trying to cut:

Here is a picture of the final result, with some issues highlighted:

The cut is done in 3 passes. First pass is a rough cut with 1mm material left over. Second is left-right parallel with a 1mm ball nose and 0.2mm left over. Final is a chevron cut with a 0.5mm ball nose. In most of the highlighted areas, you can see where the 3rd pass did not remove the leftover marks from the 2nd pass. The small highlighted area is where the "whisker" of the fish was completely cut away by the third pass. All of these areas are on the same side of the profile: toward the front of the cut (so, -Y on the machine), with a slight bias toward the right (+X on the machine). This is worrying me, because it's like the whole 3rd pass is offset slightly toward the front of the machine.

I homed the machine after each tool change (there is no automatic tool changer on the machine) and re-probed the depth. Is this sort of artifact normal, or does it mean there's a problem somewhere? Any advice would be appreciated.

I can't redistribute the model I'm using, so instead here are screenshots of the tools and operations used. Hope that is sufficient for any information you need. If it helps, the machine is a TwoTrees TTC450 Pro with the 500W spindle. Gcode is exported from PixelCNC and run directly on the machine.

Thank you for your time.